- Managing Construction Assignment

- Introduction: Managing Construction Assignment

- Question 1.

- From the main contractor:

- From specialist contractors:

- From the site workforce:

- Question 2.

- From the perspective of the design team:

- From the perspective of the principal contractor:

- From the perspective of the suppliers of prefabricated components:

- Question 3.

- 1. Segment customers based on service needs:

- 2. Customize the logistics network:

- 3. Plan in accordance with market demand signals:

- 4. Differentiate the product closer to the customer:

- 5. Source strategically:

- 6. Develop a technology strategy for the entire supply chain:

- 7. Adopt channel-spanning performance measures:

Managing Construction Assignment

Introduction: Managing Construction Assignment

Native Assignment Help provides assignment help to assist students in the research, writing, and proofreading process.

Question 1.

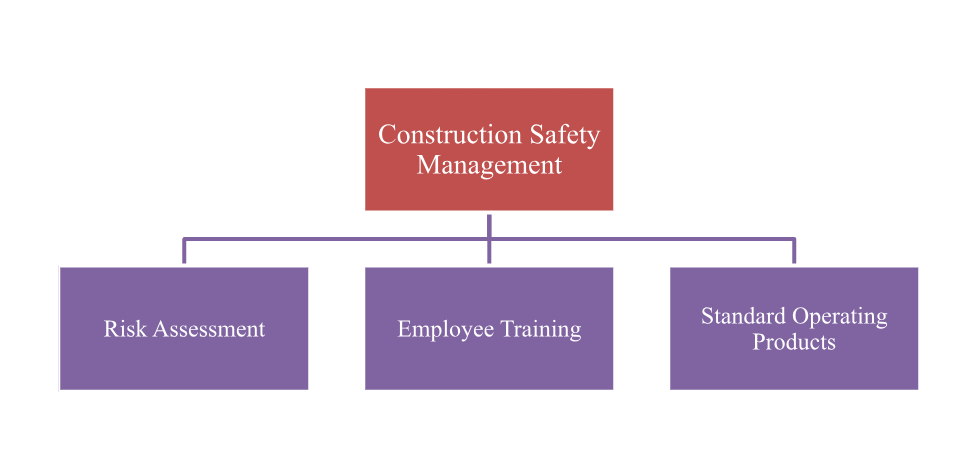

Construction management is important because it controls when projects start and when they are finished. They are the ones who are accountable for ensuring the project's cost and quality. Construction refers to the methods used to construct bridges, buildings, and other structures. Therefore, it is essential to take the necessary precautions for the health and safety of the construction site workers. Because construction involves risk, it is necessary to protect each worker. A method for managing safety activities to ensure a safe working environment on construction sites is construction safety management (Kabirifar et al. 2020). The choices made during the planning and design phases have a significant impact on construction safety. Because it is carried out on a large scale, both manpower and technology are required. In addition, no member of the construction should exhibit causality because doing so could be detrimental to an individual. For the individual's safety, a change in time necessitates a shift in management structure and procedures. Taking health and safety into account will not only ensure the worker's safety but also have a significant impact on the work they do. In addition, these factors must be implemented so that they can monitor quality and long-term growth in the future.

Different steps are taken from different perspectives to ensure safety precautions on the construction site.

From the main contractor:

The main contractor's role is to ensure the safety of the worker working at the construction site. In general, safer and precaution plays a crucial role in the field of construction and manufacturing site. As construction always deals with large machines, different technology, and other equipment. They are also responsible for reading awareness of the safety of the workers before starting up the project (Levy, 2018). They also supervise their team member in the matters to prevent accidents through misuse of any machinery ort rather equipment. It will lead the project to stop and hence, the chance to cross the deadline will increase. Safety measures in any construction will enhance performance. The necessary steps taken by the main contractors are:

- The workers' protective equipment needs to fit them and should be maintained clean. Additionally, the employees must be informed on how and when to utilize the safety equipment.

- The project manager should assume responsibility in these circumstances and be prepared to cease work if necessary.

- Lifting risks can be lethal or disabling. As a result, the maintenance workers should notify as quickly as they notice a problem.

- Strict adherence to safety regulations and procedures is required. Each safety officer must make sure that each staff member is aware of the importance of the techniques.

From specialist contractors:

Site inspections are carried out by safety personnel to find unsafe conditions. For overcoming them, we must also develop policies and regulations (Babalola et al. 2019). Workers in the construction industry, for instance, are at risk from defective tools and broken equipment, and safety personnel is in charge of finding these problems.

- The debris and dust can be extremely toxic and cause serious illnesses in the respiratory system. As a result, using dusty equipment necessitates the use of a respirator.

- Major catastrophes can be avoided with minimal worker and contractor attention. A construction manager's other major safety concern is ladder safety, though.

- The construction manager should make sure that the workers working at the construction site do not get used to crowding around new equipment and machinery, even though this is common as it can become a habit for them.

- As soon as the workers fully absorb the company's ideals and values, it will be easy to meet the safety standards (Akinlolu et al. 2020). A society that cares about the well-being of other people can greatly improve the morale of the workplace.

- From plant and equipment manufacturers: Nearly every construction project calls for substantial machinery. But if not used correctly, it can be very dangerous. When working with or near heavy equipment, common injuries include capsizing, accidental collisions, and being caught in or involved in an accident. Despite this, hazard identification, control, appropriate protection, and safety training can significantly raise production environment safety standards (Li and Liu, 2019). Protect the environment and people from the dangers posed by technical systems. The primary objective of “process and system safety” (PPS) is to guard against dangers in technical systems that affect people and the environment. Risks are always present with technology.

- In order for workers to safely operate the equipment they work on, they need to be trained in the proper procedures. Proper training and hands-on instruction should make up the majority of training. The lifting and carrying capabilities of the equipment they use must be clearly understood by them.

- When working in tighter spaces, operators at the construction site should be aware of their swing radius to avoid hitting other workers, bystanders, or nearby vehicles or equipment.

- Before using heavy equipment, conduct a visual inspection to ensure that it is in good working order (Ding et al. 2018). Examine the tracks and tires for damage and wear. When powering up equipment, check that lights, gauges, horns, and backup alarms are working properly. Check that every arm, shovel, bucket, etc. is extended completely in all directions. Ensure that the cabin can rotate in all directions if it rotates.

- The rollover security framework that is introduced on the gear is expected to protect the workers on such an occasion. They would not be thrown from the cab or jerked around if they wear a seatbelt.

From the site workforce:

Building and construction site managers ensure that projects are completed safely, within budget, and on time. From the initial preparation of the site through the final finishing, supervise and direct various contractors as well as subcontractors' activities from start to finish. The site workforce is responsible to look at the safety of their workers to enhance the performance of the work (Babalola et al. 2018). Additionally, employers should learn about the safety and security requirements of their employees. This further develops the efficiency and the nature of items and administrations.

- Costs for replacing or repairing industrial equipment will result from damage. Costs are reduced and profits are increased when injuries sustained on the job and damage to industrial equipment are prevented.

- Machines, Chemicals, electronics, and other potential workplace hazards may be encountered by employees. Personal protective equipment must be provided to these employees by their employers or the managers who take responsibility.

- All workplace accidents must be investigated by all employers. Encourage employees to adhere to all safety procedures (Gul and Ak, 2018). Additionally, any possibility of noncompliance must be explicitly stated in writing by employers. Errors are less likely because of this.

Figure 1: Construction safety management

Question 2.

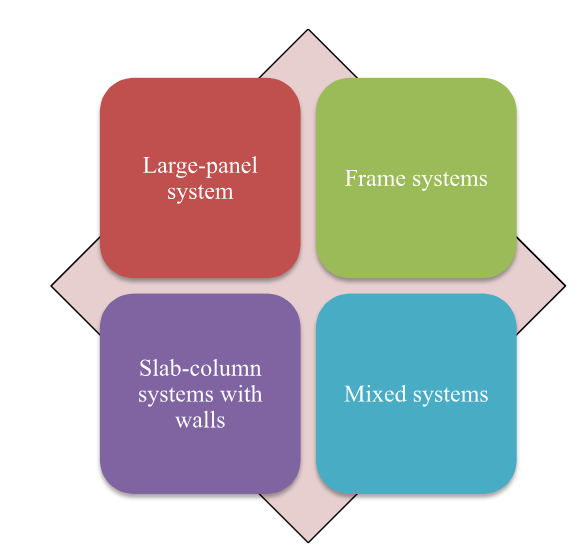

Offsite prefabrication is now more cost-effective and practical than ever before. It is the construction where the whole structure of the construction is pre-built before it is transported to its final location. Prefabrication eliminates the need to bring a large number of skilled workers to the location as well as other limiting factors like a lack of power, water, inclement weather, or hazardous conditions. Costs and risks associated with on-site cutting and welding are reduced when steel sections are prefabricated. Multi-family housing and multi-family housing complexes are constructed using this method. Construction's industrialization cannot happen without this. Doors, roof trusses, stairs, wall panels, floor panels, window walls, room-sized components, and even entire buildings are examples of prefabricated units (Ayob et al. 2018). The main benefits of prefabrications include safety and security, it saves time, providing flexibility, etc. By externally assembling components, the procedure reduces waste and eliminates the requirement for conventionally sourced building materials. Prefabrication eliminates the need to transport a large number of skilled workers to the site and other restrictive conditions like lack of power, water, inclement weather, or hazardous environments. Because partially assembled raw materials are shipped after being manufactured off-site, prefab reduces labour and material costs. However, there are advantages and disadvantages to using offsite prefabs. As a result, it is outlined below from three distinct points of view.

Figure 2: Types of Prefabrication Systems

From the perspective of the design team:

Advantages

- Contractors are already having trouble finding workers, but construction must still be done.

- Additionally, moving pre-production resources to each location is more expensive than transporting partial assemblies from a factory.

- Prefabrication makes it easier for businesses to meet deadlines, get the most out of their on-site workers, increase productivity, and succeed in the market (Kazancoglu et al. 2018).

- When compared to the same-old construction that takes place on-site, factory tools can offer more assurance of quality.

- By reducing the duration of a construction site, they simultaneously reduce its susceptibility to robbery or vandalism.

Disadvantages

- The design and construction of modular buildings necessitate extensive collaboration among project participants, particularly structural engineers, manufacturers, and architects.

- Because of their shorter economic existence, these buildings typically depreciate more rapidly than standard site-built housing.

- Maintenance of labour is another concern because prefabricated construction, unlike in-situ construction, necessitates machine-oriented expertise both on the job site and during production, and requires skilled labour (Badri et al. 2018).

- The requirement despite the absence of on-site automation and skilled workers is two of the primary obstacles to implementing prefabrication technology in construction projects that require precision and accuracy.

- The joints that will connect both the main structure and the individual parts need to be able to withstand a variety of stresses.

From the perspective of the principal contractor:

Advantages

- Prefabrication technology offers a number of advantages, some of which include improved energy efficiency, reduced waste, and inspection, as well as effective construction, the quickening of work, safety, sustainability, and quality.

- Prefabrication sites can be set up in areas where labour, electricity, materials, space, and overhead costs are lower and skilled labour is more readily available.

- Performance at high energies, quality control, and factory sealing (Alsharef et al. 2021). Moreover, the off-site building provides greater levels of safety and comfort for employees.

- An earlier principal return will be possible because construction will take less time. And, the time required for building gets decreased and as a result, it lowers the cost of labour.

- Reduced the amount of waste compared to expanding nearby. Development ensures exact consistency with construction regulations and superb quality affirmation.

Disadvantages

- Heavy-duty cranes and precise measurements are needed to handle large prefabricated parts and place them on the job site.

- In order for prefabrication to be affordable, more production capacity is required. Additionally, prefabricated system installation requires skill development and native automation.

- It must be precisely arranged because heavy machinery during erection or transportation, units are likely to be damaged. And this process becomes sloppy in a crowded area.

- The costs of transporting huge prefabricated parts can be high. Due to the requirement for skilled labour, local employment may be lost (Venkatesh et al. 2020).

From the perspective of the suppliers of prefabricated components:

Advantages

- Supplying good quality prefabricated components will lead to improved supply chain management.

- Continuous demand for the components will increase the revenue of the suppliers and will engage more with different contractors.

- The smooth performance of the machine will allow the contractors to order more components in the future.

- Keeping safety measures for the workers and designing the components will address their capability (Kusi-Sarpong et al. 2019).

- Supplying better-quality of prefabricated components will increase the demand for the components from that particular supplier.

Disadvantages

- One of the main disadvantages for the suppliers of supplying prefabricated components is meeting the demand of the contractors. If the contractor suddenly demands a large number of components then suppliers won't be able to fulfil their wants.

- Storing a large number of prefabricated components there will be the chance of damaging the components (Chen et al. 2019).

- The sudden demand for the components will allow the suppliers to consider more workers which results in the loss of the suppliers as the workers might charge the extra amount to be paid.

- Due to supplying a large number of prefabricated components, the suppliers might not meet the quality of the products resulting in losing the contractors.

- There will be the possibility of changing the design as well as plans.

Question 3.

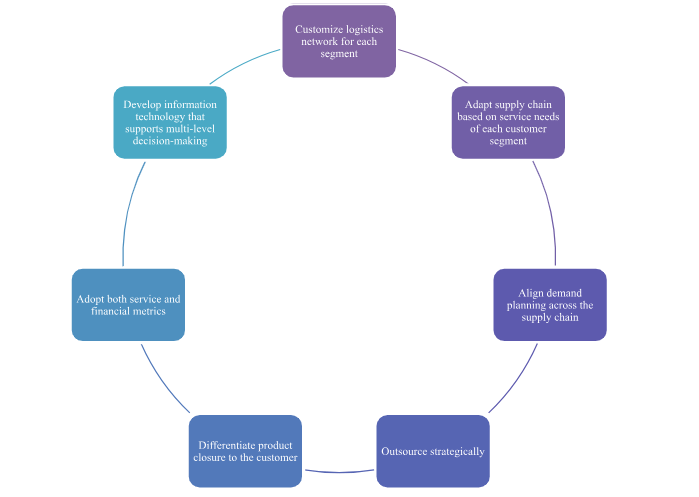

In the construction industry, supply chain management is crucial for ensuring the quality and profitability of construction projects while also improving the coordination and communication among all the stakeholders in the construction value chain. One of this system's most crucial aspects is production. This can only happen if the other parts of the supply chain work together. Beginning the production process necessitates proper planning, delivery of goods, and inventory management. Additionally, from the contractor's perspective, the primary goal of the supply chain process is to increase the value of projects in order to better manage contractor-company supplier relationships. Consolidating construction project activities is made even easier by this. Take into account, given the UK's construction projects, and landmark images the supply chain evolution process necessitates conceptual initiatives like "Building down Barriers," which the UK Ministry of Defence is compiling (Duan et al. 2020). Controlling the price of raw materials is the primary impetus for the improved supply chain management. The principles of “supply chain management” assist in managing the design process and preserving functional requirements.

Figure 3: Principle of Supply Chain Management

From the perspective of a general contractor, the key principles of supply chain management are discussed below.

1. Segment customers based on service needs:

Customer segments are the first principle. From the perspective of a general contractor, customer segments focus on requirements and are categorized accordingly. Customer segmentation is seen as a way to divide construction industry customers into groups based on their needs, actions, and other characteristics. Supply chain management of the industry can become more effective with the assistance of customer segmentation (Jang et al. 2022). It also focuses on the target customers, which ultimately leads to better supply chain management in the construction sector.

2. Customize the logistics network:

The second rule of the production network the executives assist us with conveying the best help insight. Flexibility and the ability to share people and facilities are key benefits of customizing your logistics network. This allows you to move resources around and ensure that all of your customer's requirements are met. Since the prime contractor is in charge of the project, this is important because it helps provide better service to customers. Aside from that, the prime contractor benefits because there are no additional costs involved. The contractor is accountable for completing the project within the allotted budget.

3. Plan in accordance with market demand signals:

Contractors are able to concentrate on cumulative forecasts thanks to the third principle of supply chain management. Contractors should make plans after researching and analyzing market signals. Most importantly, market demand forecasting ought to be carried out across all functional areas rather than just within each department. A common operational objective of minimizing expenses, reducing inventory, and maximizing profits must be pursued by each department. Contractors must forecast essential supply chain components in order to support customers and cut costs. It helps the construction industry finish plans on time, and save money on storage and budgets for price volatility.

4. Differentiate the product closer to the customer:

The fourth guiding principle of supply chain management emphasizes offering a variety of product options to cater to various customer groups. Because every customer has unique requirements, contractors must conduct market research and develop strategies to meet those requirements. Product differentiation ought to be based on the requirements of customers. Because no single standard component can satisfy all customer requirements, product differentiation is essential. The components must be able to be changed, redesigned, and modified, and they must be readily available to the end user. The lead times for some of the redesigned plans or parts should be shorter. For accomplishing this, schedule and component flexibility should be available as close to the end of production as possible.

5. Source strategically:

Before outsourcing any or all of the work of the contractors, they should consider their options strategically. The fifth principle states that multiple players in procurement are necessary to get the best service deals and keep the market competitive. The main contractor of the construction site should be able to know the cost of their suppliers will ultimately be the cost of the end users. Any contractor must be able to see that the cost to the supplier is also the cost to the business indirectly. In order to lower market prices and increase profit margins, distributors should collaborate to cut costs. It is the responsibility of the contractors to take the matter seriously.

6. Develop a technology strategy for the entire supply chain:

The sixth principle of supply chain management is developing a supply chain-wide technology strategy. Technology is used to improve the sustainability and effectiveness of construction management and site operations. Construction robotics, cutting-edge building materials, and building information modelling (BIM) are important to the construction industry trends (Hou et al. 2022). BIM is the “Common Data Environment” that will aid the contractors to facilitate the visualization of all data in one location. Analyse how their work is structured and designed. Assist them with arranging the assets they really want or work with expert providers

7. Adopt channel-spanning performance measures:

Adopting cross-channel KPIs is the seventh principle of supply chain management. The contractor cannot identify new opportunities for improvement or determine success unless the performance is regularly monitored and measured. Each supply chain management should have its own scorecard that shows how well goals and objectives were met. Additionally, the process is able to demonstrate a particular area of expertise and determine the extent to which this expertise can be utilized for the improvement of the supply chain management process as a whole.

Hence, supply chain management will help the contractors in achieving the numerous objectives of the project.

Reference list

Journals

Akinlolu, M., Haupt, T.C., Edwards, D.J. and Simpeh, F., 2020. A bibliometric review of the status and emerging research trends in construction safety management technologies. International Journal of Construction Management, pp.1-13.

Alsharef, A., Banerjee, S., Uddin, S.J., Albert, A. and Jaselskis, E., 2021. Early impacts of the COVID-19 pandemic on the United States construction industry. International journal of environmental research and public health, 18(4), p.1559.

Ayob, A., Shaari, A.A., Zaki, M.F.M. and Munaaim, M.A.C., 2018, April. Fatal occupational injuries in the Malaysian construction sector–causes and accidental agents. In IOP Conference Series: Earth and Environmental Science (Vol. 140, No. 1, p. 012095). IOP Publishing.

Babalola, O., Ibem, E.O. and Ezema, I.C., 2019. Implementation of lean practices in the construction industry: A systematic review. Building and Environment, 148, pp.34-43.

Babalola, O., Ibem, E.O. and Ezema, I.C., 2019. Implementation of lean practices in the construction industry: A systematic review. Building and Environment, 148, pp.34-43.

Badri, A., Boudreau-Trudel, B. and Souissi, A.S., 2018. Occupational health and safety in the industry 4.0 era: A cause for major concern?. Safety science, 109, pp.403-411.

Blanchard, D., 2021. Supply chain management best practices. John Wiley & Sons.

Chen, H.Y., Das, A. and Ivanov, D., 2019. Building resilience and managing post-disruption supply chain recovery: Lessons from the information and communication technology industry. International Journal of Information Management, 49, pp.330-342.

Ding, Z., Zhu, M., Tam, V.W., Yi, G. and Tran, C.N., 2018. A system dynamics-based environmental benefit assessment model of construction waste reduction management at the design and construction stages. Journal of cleaner production, 176, pp.676-692.

Duan, J., Zhang, C., Gong, Y., Brown, S. and Li, Z., 2020. A content-analysis based literature review in blockchain adoption within food supply chain. International journal of environmental research and public health, 17(5), p.1784.

Gul, M. and Ak, M.F., 2018. A comparative outline for quantifying risk ratings in occupational health and safety risk assessment. Journal of cleaner production, 196, pp.653-664.

Hou, L., Tan, Y., Luo, W., Xu, S., Mao, C. and Moon, S., 2022. Towards a more extensive application of off-site construction: a technological review. International Journal of Construction Management, 22(11), pp.2154-2165.

Hu, X., Chong, H.Y., Wang, X. and London, K., 2019. Understanding stakeholders in off-site manufacturing: A literature review. Journal of Construction Engineering and Management, 145(8), p.03119003.

Jang, Y., Lee, J.M. and Son, J., 2022. Development and application of an integrated management system for off-site construction projects. Buildings, 12(7), p.1063.

Kabirifar, K., Mojtahedi, M., Wang, C. and Tam, V.W., 2020. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. Journal of Cleaner Production, 263, p.121265.

Kazancoglu, Y., Kazancoglu, I. and Sagnak, M., 2018. A new holistic conceptual framework for green supply chain management performance assessment based on circular economy. Journal of cleaner production, 195, pp.1282-1299.

Kusi-Sarpong, S., Gupta, H. and Sarkis, J., 2019. A supply chain sustainability innovation framework and evaluation methodology. International Journal of Production Research, 57(7), pp.1990-2008.

Levy, S.M., 2018. Project management in construction. McGraw-Hill Education.

Li, Y. and Liu, C., 2019. Applications of multirotor drone technologies in construction management. International Journal of Construction Management, 19(5), pp.401-412.

Venkatesh, V.G., Kang, K., Wang, B., Zhong, R.Y. and Zhang, A., 2020. System architecture for blockchain based transparency of supply chain social sustainability. Robotics and Computer-Integrated Manufacturing, 63, p.101896.

World Health Organization, 2019. Consolidated guideline on sexual and reproductive health and rights of women living with HIV: web annex: community-led strategies for implementation (No. WHO/RHR/17.33). World Health Organization.