Piling Foundation Method Statement Case study

Gain insights into piling foundation methods and construction planning with a real-time case study by UK experts at Native Assignment Help.

Ph.D. Experts For Best Assistance

Plagiarism Free Content

AI Free Content

Introduction: Piling Foundation Method Statement

The reports discuss piling foundations in construction methods and several steps in piling foundations. Furthermore, methods of piling are discussed in reports as well as phases used in piling foundations. Employer requirements are mentioned in report as well as training is required for employees are also mentioned. Reports also include a description of tools and equipment that is required on-site. PPE tools that can be used on the site and firefighting measures are included. Management can create policies on site that are mention in a report to reduce risks of fire hazards on site.

Click here to access top-notch assignment help provided by our native assignment help company

Section A

1. Master Program

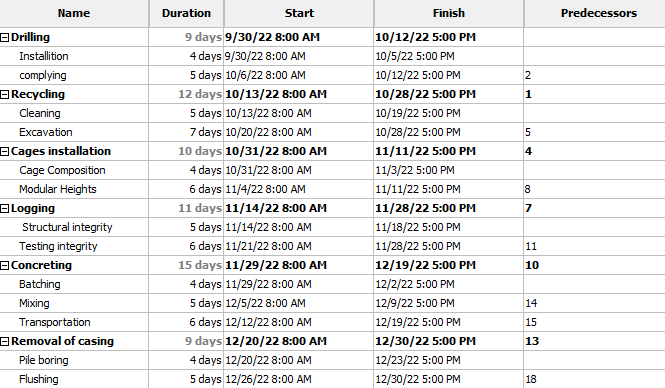

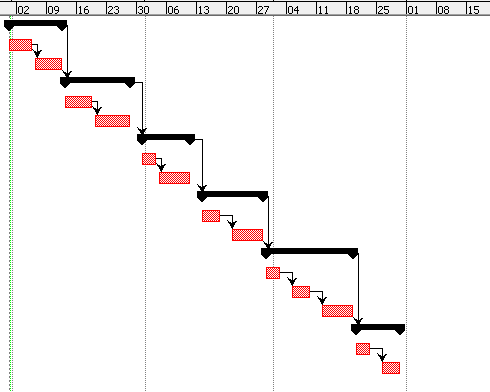

Figure 1: Timeline

Figure 2: Gantt chart

2. Method Statement

a) Piling Foundation process

Drilling of pile borehole

While setting the drilling rig at the pile location obstacles are removed by the main contractor on site. An approved pile layout can be installed in the pile center and a marked platform and casing can be at ground level (Shan et al. 2020). Engineer approval is necessary for prior use of a vibrator as well a temporary casing can be used to ensure distortion and uniform cross-section through length. Engineers on the worksite can use two steel pins installed equidistant from the pile location. The verticality of the steel casing can be checked by spirit level in a perpendicular direction. Along with this verticality can be controlled by using an inclinometer fixed at the boom of the machine. The pile can be drilled from 2.25m -12.5m away from the drilling platform and engineers can use a temporary casing to support the system.

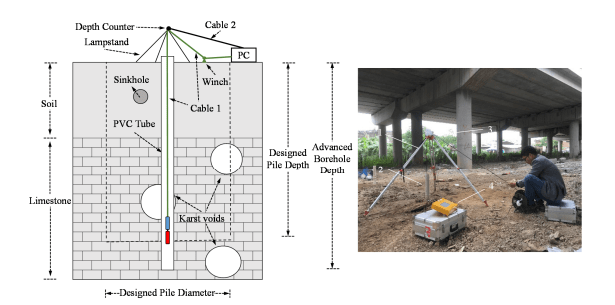

Figure 3: Single Borehole detect borehole at pile location

Engineers can use single-board radar detection, which is shown in the above figure to support engineers in identifying objects. Boulders and kart voids are randomly distributed at pile location that affects bearing capacity. Cylindrical bodies are made from concrete which is a bored pile that is installed at ground levels.

Recycling bentonite and checking

The cleaning process of bentonite suspension from soil, and sands to keep their quality well maintained and allows limits called recycling. Bentonite quality sample is taken from the bottom and top of the borehole (Reiffsteck et al. 2020). In case, excessive sand is identified in the sample then fresh bentonite is pumped through a sealed pipe. Excavations are completed before the bentonite slurry is removed from the concrete. Along with this, suspension from the borehole is pumped through descending order during concreting. In this regard, engineers cleaned plants, and bentonite is pumped through the bentonite tank for next use. Furthermore, the cleaning operation of the bottom borehole is done through a bucket.

Supports fluid can follow rigorous standard quality and engineers ensure that are checked during all work d-wall works. However, engineers can especially check before installing the cage and pouring concrete to ensure good quality. After support, fluid comes in contact with liquefied soil during the process of excavation then bentonite scullery loses its quality and ability.

Reinforcement cage installation

Steel bar cages are circular mesh pads that are made from carbon steel bars through the welding process. Cage is used in piles to provide strength in vertical concrete columns, especially in case soil quality is poor. In case, engineers do not use the cage in the pillar then the pile does not get sufficient strength to provide support to the pillar and is not able to hold the weight of a building. According to an illustration by Wang (2018), pile center devotion can be checked properly to ensure safety and deviation can be less than 1.0 centimeters. Raw materials used in construction such as steel cages can be double controlled and qualified. Welder is certified in their work before steel cages are produced for the site. In this regard, steel cage production can follow piling and lifting controls strictly to ensure safety in the workplace. In case, employees in the workplace are not able to control the lifting process of the cage during the construction process. Then, the risk of accidents can be enhanced in the workplace, which can impact on the working process of employees.

Sonic logging Tube installation

Propagation times this one method as well as balance energy between two parallel water-filled tubes with the help of sound waves. Along with this, it helps to identify specific spaces at the starting time of construction. In this method, engineers use a steel pipe system for indenting the quality of concrete that plays a significant role in the strength as well as the safety of the constructed project. On the other hand, it helps in identifying the consistency and integrity of the contract.

In this method, the developer measures breed in piles and while of drills and uses sound waves between pliers. Along with this, with the help of an ultrasonic receiver and transmitter constructor can fix test tubes between concrete from top to bottom (Zhussupbekov & Shakirova, 2021). Moreover, the drilling process of the Pillar in depth at this shaft can damage it. In this regard, in the drilling process constructor uses several resources according to their working condition on site. Along with this, shafts pacer Rebar wheels guide positing that is used in caisson construction.

Concreting

In this stage, the constructor uses resources to provide the final structure of a project and it is a final process of construction. Along with this, the constructor uses the basic material that is necessary to provide solidification within minimum time such as sand, small stone, cement, water, and some chemicals.

Chemicals play a significant role in the combination of each material of concrete within the minimum possible in any region. Per constructor uses four types of concrete as per the requirement of the project: reinforced concrete, high-strength concrete, lightweight concrete, and high-performance concrete.

Remove Temporary Guide Casing

At the starting time of concreting, providing support to concrete workers provides a temporary strength to the project. Along with this, after completing the concrete after some time workers remove it temporarily by achieving the appropriate strength of concrete. The constructor according to the construction of a project uses mainly four types of temporary guide casing. Along with this, first, one is driven guide casing, aggregate casing, boring cast, and last cast and driven casing (Tensar.co.uk, 2022). In this regard, constructors use a type of resource as per requirement that plays a significant role in completing the concrete part of a project within time.

b) Piling Foundation safety precaution

Resources required to complete the project

Multiple piles of driving equipment are used in completed projects in the UK. Along with this, piling rigs is combinations of a few leaders that are constructed from tabular elements fixed on the base of the crane. In this regard, an operator can adjust the leader by using a screw and this is used for installing a series of piles without moving equipment.

Piling winches are second pieces of equipment that are used for providing support to leaders in times of rotation and ranking. Along with this, it works as various pile sources such as hydraulic power, and petrol and diesel engines all of the mentioned equipment applies as powering winches to completed piling projects (Theconstructor.org, 2022). On the other hand, the constructor uses a hanging leader with the help of a jib crane. Specification of the mentioned equipment constructor can change the length of leaders as per the requirement of a site, which is connected, with a foot of the machine frame. Hammer guide used for installation of piles in different working site constructor uses mentioned devices for quick pillars on a working site. However, the pressure of the hammer guide is high which plays a significant role in the installation of a Pillar on any type of soil.

The last piece of equipment that is used in pile project hammer constructors uses a variety of hammers as per the requirement of the working site. However, weight, as well as size, varies as per the resistance of the ground. Along with this, if the constructor needs to install rope in a river or wet ground in time operator uses a less-weight hammer (Klages, & von Estorff, 2021). On the other hand, constructors use high-weight hammers on hard ground or hilly regions in their projects. Along with this, before using a hammer constructor needs to check the strength of the rope, because if the strength of a rope is not effective changes of damage.

Requirement of Labor

In piling, the constructor required several workers to complete the project according to the design as well as under budget. Along with this, first, constructors need one supervisor for each working site about 3 to 5 project machine operators, and 9 to 12 site operators under one supervisor (Dolati & Mehrabi, 2022). The supervisor role guides machine operators as well as site operators according to a provided design by a constructor. This is necessary for completing work within the budget as well as the strength of the project by use of instructed materials and resources in construction. On the other hand, a designated supervisor can easily distribute work to each worker who plays a significant role in regulating the whole project at the same time.

Emergency

A constructor always needs to have a first aid kit available on every working site that plays an effective role in the recovery of workers from any type of small hazards and diseases. Along with this, a few necessary things are available such as plaster, general medicines, spray, decomposable globes, etc. The second necessary thing is a fire extinguisher, necessary for working, in case a short circuit in heavy equipment can produce fire.

|

First Aids |

Communicated with the project manager |

|

Fire procedure |

Reduces maximum damage to heavy equipment with help of different fire resistance resources |

Table 1: Emergency Procedure

Impact on Environment

During piling, several heavy equipment is used to complete work within time. Along with this, it causes working machines to produce high noise as well as vibration. In this regard, constructors need minimum use of heavy equipment in piling to reduce noise pollution as well as carbon emission that is generated due to the commission of fuel in heavy types of equipment (Steel Piling Group.org, 2022). This causes during use of heavy equipment in piling project construction need to use effective precautions that help to reduce noise pollution through vibration and noises of types of equipment.

An engineer can do soil testing properly before starting their piling foundation at a construction site. In case, engineers do not do soil testing before starting their work on the project then well-quality projects cannot be delivered to their clients. Piles cannot be cast up to a minimum height of 600 mm and above level for pile foundation (Wang et al. 2021). Engineers can use Tremie pipe during their construction process to make uniform and smooth cross-sections inside. Along with this engineers, cannot construct another pile within 3 meters of the newly cast pile. Engineers can construct new piles until the new cast pile completes its 24 hours.

Methods of pile driving

Pile driving is categorized into several functions that include dropping weight, vibration, jetting, explosion, and jacking. The first method is the drop hammer method for pile driving which includes the hammer being raised to a suitable height and striking to pile head. Along with this, a vibratory hammer is an electrically powered hammer that consists of rotation (Staubach et al. 2022). However, engineers used vibratory methods for sandy and gravelly soil.

PPE

In construction projects, several potential hazards include falling objects, fire, and electric hazards. Along with this, management needs to follow safety precautions during their work process to provide safety to their employees (Sanni et al. 2020). In case, management is not able to provide essential PPE equipment to employees then the risk of injuries is enhanced in the workplace. Therefore, management can ensure that employees are using their protective equipment during their work. Employees working on height are using rope to reduce the risk of falling. On another side, a net is used in construction to reduce the risks that falling objects and injuring grounded employees.

PPE equipment includes protective clothing that can be used by employees in the workplace. However, pile processing uses heavy machinery on work sites therefore management can recommend to their employees to use earplugs in their working process to reduce the risk of ear damage (Hosny et al. 2018). Employees in the workplace to reduce the risk of eye damage can use eye protection equipment. Along with this, hard helmets can be given to employees to protect their heads of employees. Furthermore, management also ensures that employees are using hard boots in their construction process because employees are involved in concrete work. In case, employees do not use hard boots during their groundwork then the risk of leg injuries can be increased in the workplace (Rafindadi et al. 2022). In this regard, management allows employees to use gloves in their work process, which supports employees to make sufficient grip on equipment. In case, employees do not use gloves in their working process then the risk of accidents can be enhanced in the workplace.

The above-mentioned figure includes PPE equipment that is used on construction sites as well as materials that are involved in the construction process. The hook is used in the construction process to lift heavy materials from one place to another and during pile foundation; it is used to move steel cage structures from one place to another. Fences are used to surround construction sites and work as barriers for a known person to visit on-site.

Fire Fighting Measures

Flammable materials are stored in warehouses and no ignition source can be used in a warehouse. Management can implement smoking policies that allow smokers to smoke in limited smoke zone areas. Restriction related to the use of a heater in the working area and proper training can be provided to employees to deal with fire hazards. Fire extinguishers can be placed and all members can access those extinguishers (Garcia et al. 2019). The staff cabin also includes fire extinguishers that can be used according to requirements. On the other hand, management ensures that a proper electric circuit is created on-site to reduce risks of fire hazards.

Section B

Planning software and its applications

The designer selected the Asta Power Project to provide a total solution for their pile construction project to the constructor. The designer selected the mentioned software for the planning of the project due to some of its advantages. Along with this, it is very easy to use as well as an affordable tool that supports the designed workflow of mentioned projects and analyzes every work easily such as workers, project managers, and schedulers (Zaher & Marzouk, 2018). On the other hand, it is used for several methods for setup activities including types of activities that occurred to complete the project, bar chart, and task pools. Along with this, a constructor can easily use resources and codes of activity in drops and drag.

Presentation quality

Constructors use the mentioned software to make a quality presentation of the project with minimum effort. Along with this, the developer easily focused on important information including text, images of the project, graphics representation of project quality, and each step of a project. In a presentation, a time developer can easily focus on selected aspects with the help of a bar chart as well as resources that are used to complete the project within time (Liu et al. 2022). Along with this, a developer can provide videos of the working efficiency of equipment that help in understanding the working procedure of the project.

Designers provide more accurate and precise schedules

The project designer can easily provide schedules and draw every step and activity table, and the software easily links tasks automatically. In this regard, during making activities, the developer does not need to select a calendar Asta power project always uses correct calendars in time linking with multitasking. This is one of the effective properties of the mentioned software that helps program developers to provide an effective schedule of completion as well as a total number of workers. On the other hand, with the help of mentioned quickly share project plans with a viewer of a project without any cost.

Benefits of using Asta Power Project

The major advantage of the Asta power project in piling projects is that it is easy to use in developing effective plans quickly. With help of the mentioned software constructor can easily filter plans and provide sub-contracts to complete the project within time. In case of delay due to any causes, it provides effective protection to complete the project within time. Along with this, it provides simple printing of projects that helps in understanding employees.

Construct planning software

This is another construction planning software that can be used by a homebuilder to provide project details as well as predict financial costs to clients. Along with this, it allows users to synchronize estimated data, and select procedures of working, which helps to provide budgets with online or QuickBooks desktop (D'Elia, 2021). In this regard, it offers communication with clients and provides details of the scheduling of working building homes. In other words, the mentioned software applies only to small construction projects or building homes. On the other hand, operating cost is very low against the above-mentioned planning software, because it is suitable only for analyzing small construction projects.

Conclusion

The report summarized that the piling foundation includes six phases for pile foundation. In this regard, stages include drilling, reinforcement, logging, concreting, and removal. Engineers ensure that all phases are executed properly to provide strength in the pile foundation. In case, management is not able to complete all mentioned phases properly then engineers cannot able to maintain quality in their work process. The report also summarized safety precaution that is mentioned in the above section to provide a safe environment for employees. PPE equipment includes helmets, shoes, and others; therefore, employees can perform well in their work. In case, management does not provide essential equipment to employees then employees cannot able to perform well in their tasks. Therefore, management needs to provide essential equipment to employees otherwise; employees will not able to perform well in their tasks. However, management implemented several policies to reduce the risk of hazards in the workplace. Such as smoking policies are implemented to reduce the risk of fire hazards and fire extinguishers are placed on work sites to use in emergencies.

Reference List

António, S. A. M. N. (2021). Analysis on bentonite support fluid recycling using desanders, desilters, and centrifuges for the Diaphragm-Wall excavation in adverse geological conditions: The Chilterns' Chalk.

D'Elia, T. M. (2021). New Teacher Induction: Locating New Teacher Needs to Co-Construct Induction Programs. Montclair State University. Retrieved from: https://link.springer.com/article/10.1007/s10796-021-10238-1

Dolati, S. S. K., & Mehrabi, A. (2022). FRP sheet/jacket system as an alternative method for splicing prestressed-precast concrete piles. Case Studies in Construction Materials, 16, e00912. Retrieved from: https://www.sciencedirect.com/science/article/pii/S2214509522000444

Duan, R., Deng, H., Tian, M., Deng, Y., & Lin, J. (2022). SODA: A large-scale open-site object detection dataset for deep learning in construction. Automation in Construction, 142, 104499.

Garcia-Martin, R., González-Briones, A., & Corchado, J. M. (2019). Smartfire: Intelligent platform for monitoring fire extinguishers and their building environment. Sensors, 19(10), 2390.

Hosny, H. E., Ibrahim, A. H., & Fraig, R. F. (2018). Risk management framework for Continuous Flight Auger piles construction in Egypt. Alexandria Engineering Journal, 57(4), 2667-2677.

Klages, E., Lippert, S., & von Estorff, O. (2021, June). A noise-reduced impact hammer for offshore pile driving. In Proceedings of Meetings on Acoustics UACE (Vol. 44, No. 1, p. 070016). Acoustical Society of America. Retrieved from: https://asa.scitation.org/doi/pdf/10.1121/2.0001482

Liu, H., Liu, G., Wang, H., Wan, H., Xu, X., Shen, C., ... & He, Q. (2022). Preparation and Performance Study of Large Volume Foamed Lightweight Soil for an Intelligent Networked Vehicle Test Site. Materials, 15(15), 5382. Retrieved from: https://doi.org/10.3390/ma15155382

Liu, L., Shi, Z., Peng, M., & Tsoflias, G. P. (2020). Investigation of Geological Anomalies at Pile Foundation Location in Urban Karst Areas Using Single Borehole Radar. Geosciences, 10(6), 232.

Projectsanalytics.com, (2022). How To Use Asta Powerproject’s Drag and Drop Feature To Create Accurate Schedules, Viewed on: 01/01/2022, Retrieved from: https://www.projectsanalytics.com/use-asta-powerprojects-drag-drop-feature-create-accurate-schedules/

Rafindadi, A. D. U., Napiah, M., Othman, I., Alarifi, H., Musa, U., & Muhammad, M. (2022). Significant factors that influence the use and non-use of personal protective equipment (PPE) on construction sites—Supervisors' perspective. Ain Shams Engineering Journal, 13(3), 101619.

Reiffsteck, P., Saussaye, L., & Habert, J. (2020). Borehole quality influence on expansion test results.

Sanni-Anibire, M. O., Mahmoud, A. S., Hassanain, M. A., & Salami, B. A. (2020). A risk assessment approach for enhancing construction safety performance. Safety science, 121, 15-29.

Shan, H. F., Xia, T. D., Yu, F., Tao, H. B., & He, S. H. (2020). Influence of Underpinning Pile Drilling Construction on the Bearing Behavior of Existing Loaded Foundation Piles: Case Study. Advances in Civil Engineering, 2020.

Shihata, M. (2018). Investigation of Visualization Needs for Vertical Repetitive Projects (Master's thesis, University of Waterloo).

Staubach, P., Machaček, J., & Wichtmann, T. (2022). Mortar contact discretisation methods incorporating interface models based on Hypoplasticity and Sanisand: application to vibratory pile driving. Computers and Geotechnics, 146, 104677.

Steelpilinggroup.org, (2022). ENVIRONMENTAL FACTORS WITH DRIVEN PILES, Retrieved from: https://www.steelpilinggroup.org/guidance/construction/environmental-factors-with-driven-piles/#:~:text=In%20the%20past%2C%20steel%20pile,and%20were%20therefore%20very%20noisy.

Tensar.co.uk, (2022). What are the types of piles and their construction methods?, Retrieved from: https://info.tensar.co.uk/blog/what-are-the-types-of-piles-and-their-construction-methods

Theconstructor.org, (2022). Purpose of Crosshole Sonic Logging (CSL) Pile Test, Retrieved from: https://theconstructor.org/geotechnical/crosshole-sonic-logging-pile-test-foundation-integrity/77956/

Theconstructor.org, (2022). Types of Pile Driving Equipments, Retrieved from: https://theconstructor.org/geotechnical/pile-driving-equipment-types-uses/17605/

Theconstructor.org, (2022). Uses of Concrete in Civil Engineering, Retrieved from: https://theconstructor.org/concrete/uses-concrete-civil-engineering/35992/

Wang, R., Li, Y., Liu, X., Zhang, S., Zhang, C., Li, Z., & Wang, P. (2021, June). Research on advantages and disadvantages of prestressed concrete hollow square pile and pipe pile in pile foundation selection. In IOP Conference Series: Earth and Environmental Science (Vol. 787, No. 1, p. 012022). IOP Publishing.

Wang, Y. (2018, February). Study on Pile Foundation Quality Control Measures of Quanzhou Sihai Building. In 2017 3rd International Forum on Energy, Environment Science and Materials (IFEESM 2017) (pp. 214-217). Atlantis Press.

Zaher, M., Greenwood, D., & Marzouk, M. (2018). Mobile augmented reality applications for construction projects. Construction Innovation, 18(2), 152-166. Retrieved from: http://nrl.northumbria.ac.uk/id/eprint/32822/1/PDF_Proof.pdf

Zhussupbekov, A., & Shakirova, N. (2021, April). Detection of Defects in Bored Piles By Non-Destructive Methods On LRT Construction Site. In IOP Conference Series: Earth and Environmental Science (Vol. 727, No. 1, p. 012026). IOP Publishing. Retrieved from: https://iopscience.iop.org/article/10.1088/1755-1315/727/1/012026/pdf

Go Through the Best and FREE Case Studies Written by Our Academic Experts!

Native Assignment Help. (2026). Retrieved from:

https://www.nativeassignmenthelp.co.uk/piling-foundation-method-statement-case-study-18169

Native Assignment Help, (2026),

https://www.nativeassignmenthelp.co.uk/piling-foundation-method-statement-case-study-18169

Native Assignment Help (2026) [Online]. Retrieved from:

https://www.nativeassignmenthelp.co.uk/piling-foundation-method-statement-case-study-18169

Native Assignment Help. (Native Assignment Help, 2026)

https://www.nativeassignmenthelp.co.uk/piling-foundation-method-statement-case-study-18169

- FreeDownload - 974 TimesCritical Assessment Of The Key Concepts In Airline Operations Case Study

Critical Assessment Of The Key Concepts In Airline Operations 1.0...View or download

- FreeDownload - 2106 TimesMeeting Consumer Needs Tesco And M&S Case Study

Introduction - Meeting Consumer Needs Tesco And M&S 1. Introduction...View or download

- FreeDownload - 779 TimesExploring Babylon Health's Innovative AI-Powered Digital Healthcare Solutions Case Study

Exploring Babylon Health's Innovative AI-Powered Digital Healthcare...View or download

- FreeDownload - 1205 TimesJoules Marketing Strategy: SWOT, PESTEL, and Targeting Middle-Aged Consumers Case Study

How Joules Targets Middle-Aged Professionals With Its Marketing Mix The...View or download

- FreeDownload - 1340 TimesSH5009QA Ethical Research in Professional Context Case Studies

SECTION 1 INTRODUCTION Ethical dilemma implies for the obstacle in decision...View or download

- FreeDownload - 789 TimesThree Theories Of Banking And The Conclusive Evidence By Richard

Three Theories Of Banking And The Conclusive Evidence By Richard A....View or download

-

100% Confidential

Your personal details and order information are kept completely private with our strict confidentiality policy.

-

On-Time Delivery

Receive your assignment exactly within the promised deadline—no delays, ever.

-

Native British Writers

Get your work crafted by highly-skilled native UK writers with strong academic expertise.

-

A+ Quality Assignments

We deliver top-notch, well-researched, and perfectly structured assignments to help you secure the highest grades.