- 1. Literature Review

- Advantages of using Statistical Process control

- Application of Statistical Process Control

- Improving the supply chain management by using SPC

- SPC can help to manage big data

- SPC helps in Transparent Sequential Learning

- Nonparametric Control Charts can be done by using SPC

- SPC is used for Monitoring Short-Range

- SPC maintains the policies for continuous production systems

- SPC is used in the more useful investigation of sequential data

- Future forecasting of supply chain management by using SPC

- 2. Statistical analysis of "Waterside Leather Limited"

- X-Bar test

- Capability test

- Recommendations

1. Literature Review

Advantages of using Statistical Process control

There are different types of advantages that can be found by using statistical process control. According to the article, the main aim of quality improvement is not to give good quality of different products. Therefore, SPC is important for increasing productivity and improving customer satisfaction (Perkasa, 2021). The supply chain process needs to be gone hand in hand with providing different companies with low costs for enhancing the quality of the service. It is reported that process control might add value in case it is utilized effectively in the process of decision-making. Therefore, product quality is dependent on the process quality that impacts directly supply chain management.

Application of Statistical Process Control

According to some articles, PSC inspections are executed in different types of supply chain management even in Port State Control. Therefore, companies execute exercise control of the manufacturing process by bringing dominion of the business, and manufacturing method, that can improve efficiency as well as quality (Yuan et al. 2020). Therefore, SPC accentuates the precluding detection of the issues in the supply chain management process. Thus, companies can do formal inspections, maintenance, testing products, and also personal advancement procedures. Therefore, it is found that companies accept control charts as the most general tools for identifying under statistical control.

Improving the supply chain management by using SPC

It is considered that SPC is a group of statistical techniques that allows the detection of differences in the measurements of collecting the baseline data. The algorithm of SPC helps to maintain the quality of the process of production. Therefore, it allows assuring that the procedure performs efficiently as well as creating more specification products with minimum scrap or waste (Stenzler, 2019). On the other hand, the charts of SPC enable the procedures the monitoring performance helps to identify the types of variations in the process. Therefore, these charts help to focus on the highlighted areas of supply chain management that might need further investigation.

SPC can help to manage big data

Sensors, satellites, mobile devices, and some other advanced technologies create data purchases more suitable. Therefore, big data applications can be identified by using the statistical process control method. Statisticians, informaticians, computer scientists, and some other data scientists have invented different types of tools for controlling this application. Hence, it is considered that the SPC might be vital for many big data applications (Qiu, 2020). However, those data have not reached much concentration from the communities of big data. Forest Science, agriculture forecasting, land research, climate science and also the monitoring of ecosystems including biodiversity conservation are big data applications. In this data science, the statistical process control uses for identifying the better quality result.

SPC helps in Transparent Sequential Learning

According to some research reports, the "Transparent Sequential Learning" (TSL)-based technique monitoring system is described. The present-time issue during sequential online operation is monitoring. In case of the TSL-based control chart contends that the corresponding function is IC, therefore, the parameter of IC estimations might get updated. Using the SPC also helps to data decor relation by observing the previous data set in SPC (Qiu and Xie, 2022). It is considered that SPC helps to enhance product quality as well as eradicate variation in the supply chain process. Thus, this allows for maintaining the observation of customer requirements as well as regulations in it.

Nonparametric Control Charts can be done by using SPC

In this research study, it is analyzed the charts of Statistical process control (SPC) utilised widely for structuring initiatives for quality control as well as supply chain management. Therefore, standard SPC charts developed for observing the production lines in manufacturing companies are especially based on the hypotheses. The data observed those are identically distributed as well as independent of the parametric distribution (Qiu, 2019). It is identified that in these SPC charts, the "control-and-adjustment" procedure usually requires to be repeated several times. Therefore, nonparametric statistical process control helps to identify the parametric process.

SPC is used for Monitoring Short-Range

It is reported that the SPC charts are vital critically for managing as well as controlling quality in manufacturing industries, disease surveillance, environmental monitoring, and many other applications. It is important to create new management charts that are suitable for monitoring serially connected data. However, Qiu et al. (2020) suggests that there are some limitations in this process such as the execution of this process being sensitive to the presumed parametric time sequence models. On other hand, the SPC process also in the manufacturing set-up takes a long time to complete. Filling out the charts and monitoring the whole process might be time-consuming sometimes.

SPC maintains the policies for continuous production systems

It is found that in some cases the quality indicator might be sported by the normal law. Therefore, the indicator might become evolve across the mean with some dispersion that refers to the standard deviation. On the other hand, the control chart is utilized to identify the abnormal behavior of the data set (Dutoit et al. 2019). Hence, the SPC cannot deliver the quality result of a production procedure. Therefore, this can be said that this process is not operated efficiently. As a result, the process needs to be re-manufactured to get the exact result for reducing rework, as well as scarp.

SPC is used in the more useful investigation of sequential data

It is identified that SPC cannot operate independently as it needs more data to operate. Thus, the SPC delivers insights on whether methods are behaving as determined as well as assists to detect the regulations in the process. The charts in the sequential data are utilized to deliver enhanced production efficiency for improving profitability, decreasing defects, and also minimizing costs (Simões et al. 2020). On the other hand, it can help to identify the types of variations in the process. Therefore, this allows the process with low costs for enhancing the quality of the service for a more useful analysis of sequential data.

Future forecasting of supply chain management by using SPC

According to some research reports, the SPC is used for future forecasting of the supply chain for looking at the previous data about the demand for products to support making more powerful business decisions in budgeting, planning, and also maintaining the stock inventory (Rustam et al. 2020). On the other hand, it also helps businesses by experiencing failure in the business, especially during the holidays of the company. The quantitative and forecasting trend is based on data analysis for getting the strongest process of supply chain management.

2. Statistical analysis of "Waterside Leather Limited"

X-Bar test

The data record with respect to the temperature of "Waterside Lager Limited" has been statistically analysed over the spreadsheet in terms of obtaining the graph forecast. The major analysis has been critically discussed in table 1 comprehensively.

| Date | X1 | X2 | X3 | X4 | Average (X-bar) | Range | X-Dbar | UCL (+35) | LCL(-35) |

| 1-Sep | 27.508 | 33.19 | 30.0649 | 30.0102 | 30.193275 | 5.682 | 30.72293 | 46.4345 | 15.01136 |

| 2-Sep | 27.6475 | 32.4864 | 24.1237 | 26.5117 | 27.692325 | 8.3627 | 30.72293 | 46.4345 | 15.01136 |

| 3-Sep | 33.9747 | 25.8427 | 31.5985 | 27.9439 | 29.83995 | 8.132 | 30.72293 | 46.4345 | 15.01136 |

| 4-Sep | 34.7521 | 31.0639 | 33.2517 | 31.5985 | 32.66655 | 3.6882 | 30.72293 | 46.4345 | 15.01136 |

| 5-Sep | 32.8441 | 25.2503 | 26.3891 | 26.3891 | 27.71815 | 7.5938 | 30.72293 | 46.4345 | 15.01136 |

| 6-Sep | 27.9969 | 29.4594 | 28.2322 | 28.2322 | 28.480175 | 1.4625 | 30.72293 | 46.4345 | 15.01136 |

| 7-Sep | 23.7669 | 27.6435 | 23.0705 | 24.8471 | 24.832 | 4.573 | 30.72293 | 46.4345 | 15.01136 |

| 8-Sep | 23.7561 | 25.3579 | 34.3809 | 27.1621 | 27.66425 | 10.6248 | 30.72293 | 46.4345 | 15.01136 |

| 9-Sep | 27.1621 | 26.8852 | 24.9195 | 32.045 | 27.75295 | 7.1255 | 30.72293 | 46.4345 | 15.01136 |

| 10-Sep | 33.6692 | 27.508 | 23.7561 | 34.3809 | 29.82855 | 10.6248 | 30.72293 | 46.4345 | 15.01136 |

| 11-Sep | 24.4551 | 30.8515 | 29.792 | 36.7611 | 30.464925 | 12.306 | 30.72293 | 46.4345 | 15.01136 |

| 12-Sep | 31.2412 | 26.8945 | 36.4552 | 33.5425 | 32.03335 | 9.5607 | 30.72293 | 46.4345 | 15.01136 |

| 13-Sep | 36.5443 | 31.8286 | 32.9976 | 29.8895 | 32.815 | 6.6548 | 30.72293 | 46.4345 | 15.01136 |

| 14-Sep | 30.5261 | 38.2822 | 32.4421 | 36.1361 | 34.346625 | 7.7561 | 30.72293 | 46.4345 | 15.01136 |

| 15-Sep | 32.6263 | 35.158 | 40.73 | 38.294 | 36.702075 | 8.1037 | 30.72293 | 46.4345 | 15.01136 |

| 16-Sep | 43.2163 | 43.8389 | 40.5347 | 38.1259 | 41.42895 | 5.713 | 30.72293 | 46.4345 | 15.01136 |

| 17-Sep | 45.2167 | 36.6261 | 44.9231 | 39.5582 | 41.581025 | 8.5906 | 30.72293 | 46.4345 | 15.01136 |

| 18-Sep | 40.6913 | 39.8205 | 38.4995 | 38.4995 | 39.3777 | 2.1918 | 30.72293 | 46.4345 | 15.01136 |

| 19-Sep | 32.3862 | 40.14 | 36.1144 | 36.5583 | 36.299725 | 7.7538 | 30.72293 | 46.4345 | 15.01136 |

| 20-Sep | 37.1615 | 41.1681 | 33.9659 | 31.4491 | 35.93615 | 9.719 | 30.72293 | 46.4345 | 15.01136 |

| 21-Sep | 29.0525 | 33.2361 | 28.9381 | 28.3651 | 29.89795 | 4.871 | 30.72293 | 46.4345 | 15.01136 |

| 22-Sep | 33.5726 | 30.9505 | 34.6799 | 36.5684 | 33.94285 | 5.6179 | 30.72293 | 46.4345 | 15.01136 |

| 23-Sep | 34.7634 | 28.6535 | 31.4899 | 35.5593 | 32.616525 | 6.9058 | 30.72293 | 46.4345 | 15.01136 |

| 24-Sep | 34.4278 | 28.3744 | 30.2776 | 26.8801 | 29.989975 | 7.5477 | 30.72293 | 46.4345 | 15.01136 |

| 25-Sep | 33.4373 | 23.7654 | 22.4613 | 31.0189 | 27.670725 | 10.976 | 30.72293 | 46.4345 | 15.01136 |

| 26-Sep | 30.7144 | 27.0994 | 26.3009 | 27.9834 | 28.024525 | 4.4135 | 30.72293 | 46.4345 | 15.01136 |

| 27-Sep | 20.6646 | 23.5196 | 26.6281 | 19.8736 | 22.671475 | 6.7545 | 30.72293 | 46.4345 | 15.01136 |

| 28-Sep | 24.9148 | 26.8165 | 28.8493 | 24.6247 | 26.301325 | 4.2246 | 30.72293 | 46.4345 | 15.01136 |

| 29-Sep | 25.5761 | 25.0189 | 19.1047 | 22.5525 | 23.06305 | 6.4714 | 30.72293 | 46.4345 | 15.01136 |

| 30-Sep | 18.8148 | 19.7404 | 16.2033 | 24.6646 | 19.855775 | 8.4613 | 30.72293 | 46.4345 | 15.01136 |

| Standard Deviation | 5.237190389 |

Table 1: Statistical analysis of "Waterside Leather Limited"

Therefore, it can be stated that temperature readings of 120 times for the month of September have been considered through this statistical analysis. Thus, 4-time temperature readings have been recorded within a single day and each time reading of every day has been denoted as X1, X2, X3 and X4. After that mean value of the average of every single day of September month has been individually calculated under the spreadsheet. Besides that, the "Upper controls limit" (UCL) and "Lower control limit" have been also calculated based on figuring out the value of the X-bar (Mahapatra et al. 2020). However, the value of UCL has been coined out by the formula of "Adding (3 x σ to the average)" and σ stands for standard deviation. Similarly, the value of LCL has been coined out by the formula of "Subtracting (3 x σ to the average)".

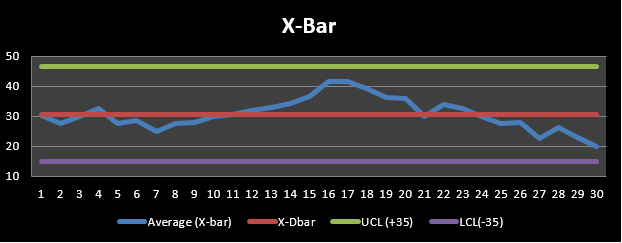

Figure 1: X-bar analysis

The temperature stability has been contemplated by using an X-bar chart in terms of analysis of temperature effluent. According to Figure 1, obtained from the statistical analysis of historic data, the different temperature fractions can be observed. It can be noticed that from day 13 to day 21 UCL have been noticed to rise under the segment of UCL and a sudden fall under LCL has been reported from the 24th of September till September 30th. Besides that, during the initial phase, the temperature was merely close to the average line of the X-bar as per the projection of variables (Abbas et al. 2018). However, a few non-conforming nature special factors need to be addressed in contrast to temperature fluctuation under the region of UCL and LCL.

In contrast to the control pattern rule of the supply chain, both upward and downward trends of temperature within September month have been recognised. Thus, it can be stated that the occurrence of such type of pattern has projected erroneous patterns in the supply chain control process. The temperature reading for September month has projected the highest UCL with nearly 41.4°C (Khan et al. 2021). However, it can be stated that the legally permitted temperature value of the discharges of the brewery needed to be kept under 40.0°C. In contrast to the scenario, revised LCL can be observed from the same figure number 1 and an out-of-control pattern has been noticed in the last few days of September month (Abbas et al. 2020). The evidence of temperature data has projected that fluctuation has occurred from the middle of the month.

Capability test

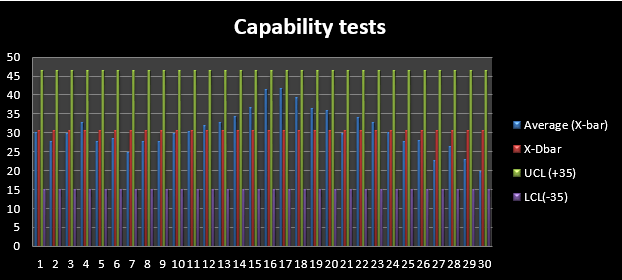

Therefore, that type of pattern reflects the instability of temperature due to the malfunction of equipment or lack of maintenance programme. Besides that, capability tests with respect to the data sets have been performed and similar projections have been noticed. The temperature needs to be ranged between 25.0°C to 35.0°C and a few UCL and LCL tendencies have been noticed from the middle of the month. The highest level of UCL and LCL has been noticed from 16th to 17th September and 30th September respectively. The capability has been measured based on Cpk=0.359 and Cp=0.4013.

Figure 2: Capability tests

Hence, it can be stated that a prospect of poor maintenance over the supply chain aspects of "Waterside Lager Limited" has been detected (Abbas et al. 2020). Thus, a few improvement aspects need to be followed by the organization in terms of efficiency over the supply chain and those recommendations have been discussed below.

Recommendations

It can be stated that the “DMAIC” cycle of six sigma needs to be followed by the organization in terms of improvement of the quality of the product. It has been observed that this type of approach has a major role in terms of addressing a special type of variable that hurts the spirit of productivity (Abbas et al. 2020). Along with that preventive measures and monitoring aspects also can be formulated depending on such factors. Thus, the core objective of using such type of model has relied on effectiveness and efficiency with respect to the existing processes of an organization (Ravichandran, 2017). Thus, this model can robustly help to address and fix the issues associated with plant of "Waterside Lager Limited".

- The goal and deliverable capability of the organization need to be defined first for the improvement of plant infrastructure.

- The current process and practices need to be measured and analysed in terms of effctive quality and performance.

- The core and concrete cause of variation with special needs to be determined for the improvement of plant infrastructure.

- The needed practice has to be adopted by the managers in terms of elimination or mitigation of such special issues.

- In the end, effective and accurate control measures need to be established in terms of monitoring productivity and efficiency.

References

Abbas, Z., Nazir, H.Z., Akhtar, N., Abid, M. and Riaz, M., 2020. On designing an efficient control chart to monitor fraction nonconforming. Quality and Reliability Engineering International, 36(2), pp.547-564.

Abbas, Z., Nazir, H.Z., Akhtar, N., Riaz, M. and Abid, M. (2018) An Enhanced Approach For The Progressive Mean Control Charts. Quality and Reliability Engineering International. 35(4), pp.1046–1060.

Abbas, Z., Nazir, H.Z., Akhtar, N., Riaz, M. and Abid, M., 2020. On designing a progressive mean chart for efficient monitoring of process location. Quality and Reliability Engineering International, 36(5), pp.1716-1730.

Abbas, Z., Nazir, H.Z., Akhtar, N., Riaz, M. and Abid, M., 2020. On developing an exponentially weighted moving average chart under progressive setup: An efficient approach to manufacturing processes. Quality and Reliability Engineering International, 36(7), pp.2569-2591.

Abid, M., Mei, S., Nazir, H.Z., Riaz, M. and Hussain, S., 2021. A mixed HWMA‐CUSUM mean chart with an application to manufacturing process. Quality and Reliability Engineering International, 37(2), pp.618-631.

Dutoit, C., Dehombreux, P., Lorphèvre, E.R. and Equeter, L., 2019. Statistical process control and maintenance policies for continuous production systems subjected to different failure impact models: literature review. Procedia CIRP, 86, pp.55-60.

Khan, Z., Gulistan, M., Kausar, N. and Park, C., 2021. Neutrosophic Rayleigh model with some basic characteristics and engineering applications. IEEE Access, 9, pp.71277-71283.

Mahapatra, A.P.K., Song, J., Shao, Z., Dong, T., Gong, Z., Paul, B. and Padhy, I. (2020) Concept Of Process Capability Indices As A Tool For Process Performance Measures And Its Pharmaceutical Application. Journal of Drug Delivery and Therapeutics. 10(5), pp.333–344.

Perkasa, L., 2021. BENEFIT USING STATISTICAL PROCESS CONTROL (SPC) FOR PROCESS CONTROL IN TEXTILE MANUFACTURING: A REVIEW. Journal of Mechanical Science and Engineering, 8(1), pp.023-028.

Qiu, P. and Xie, X., 2022. Transparent sequential learning for statistical process control of serially correlated data. Technometrics, 64(4), pp.487-501.

Qiu, P., 2019. Some recent studies in statistical process control. In Statistical quality technologies (pp. 3-19). Springer, Cham.

Qiu, P., 2020. Big data? Statistical process control can help!. The American Statistician, 74(4), pp.329-344.

Qiu, P., Li, W. and Li, J., 2020. A new process control chart for monitoring short-range serially correlated data. Technometrics, 62(1), pp.71-83.

Ravichandran, J. (2017) Control Chart For High-Quality Processes Based On Six Sigma Quality. International Journal of Quality & Reliability Management. 34(1), pp.2–17.

Rustam, F., Reshi, A.A., Mehmood, A., Ullah, S., On, B.W., Aslam, W. and Choi, G.S., 2020. COVID-19 future forecasting using supervised machine learning models. IEEE access, 8, pp.101489-101499.

Simões, R.A., Weydmann, G., Decker, R., Benvenuti, M.F., Muñoz, M.Á. and Bizarro, L., 2022. Statistical process control charts for better analysis of sequential data in psychology: The case of illusion of control experiments. Behavior Research Methods, 54(1), pp.475-492.

Stenzler, A., 2019. Improving Home COPD Monitoring Through Statistical Process Control (SPC). Respiratory Therapy, 14(4), p.43.

Yuan, C.C., Chung, W.H., Cai, C. and Sung, S.T., 2020. Application of statistical process control on port state control. Journal of Marine Science and Engineering, 8(10), p.746.