Analyzing the Supply Chain Management Of Zara Case Study

Analysis Of The Supply Chain Of Zara Case Study By Native Expert!

Ph.D. Experts For Best Assistance

Plagiarism Free Content

AI Free Content

Introduction: Analysis Of The Supply Chain Of Zara

Strategies and competing priorities are vital areas of retail business. With strategies and effective business approaches retail organizations are enhancing their competitive edge in the retail market. Zara is a chief performer in the worldwide approach business. One of the utmost trade corporations in the world, Inditex, owns it. The organization’s innovative business approach centres on the customers and encompasses product development, manufacturing, distribution, and retail sales. The corporation offers clothing and apparel to its customers in different countries and regions. The present report discusses the key performance indicators that are relevant to the organization in measuring its operational performance in the sector. Operational characteristics and business approach in planning and controlling of the operational process are also discussed in the report. Along with the operational characteristics and planning and controlling of the operation, the report also illustrates the technological application and their operations in the supply chain unit of the enterprise. The logistics and transportation management of Zara are also demonstrated in the report. On the other hand, the technologies that are used in the logistics and transportation operation of the corporation are also specified in the present report.

Need assignment help UK for academic success? Native Assignment Help is your ultimate solution. Our seasoned writers possess the expertise to craft impeccable assignments that meet the highest academic standards, guaranteeing your success.

Analysis of KPI and competitive priorities

There are several performance metrics that are used to analyze Zara’s performance and supply chain operation in the present turbulent environment. The primary focus of the organization is on the supply chain operations that result in delivering positive and effective results to its clients and customers. Defects per unit of goods and products, level of complaints and queries received from the customers, and scrap level of the goods and products are some of the performance indicators for identifying the quality of the products in the organization (Slack and Brandon-Jones, 2019). On the other hand, Zara also focuses on the efficiency and flexibility of the supply chain operations.

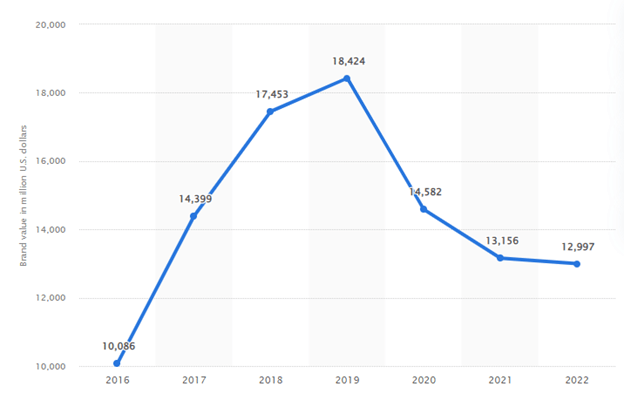

Figure 1: Brand value of Zara

Customer query time and order lead are some of the key performance indicators that are used by the organization in analyzing the efficiency of the operational process in the enterprise. The efficiency of the machines and the labor productivity define the cost of processing the goods in the business. Quality, cost, and flexibility are some of the competitive priorities of Zara (Slack and Brandon-Jones, 2019). The quality and cost of the products and its flexibility in delivering the products to the customers are some of the competitive priorities that enable the organization to gain a competitive advantage in the relevant marketplace.

Because they manufacture their own goods, Zara can guarantee prompt shipping and service. Even if they are not reliable in terms of merchandise accessibility, they are reliable in terms of maintaining relevance in the realm of fashion. The "Zara" has become associated with trendsetting styles at reasonable pricing (López et al., 2022). Due to the trade-off between low employment budgets in Asia and operative competence, Zara's labels would read "made in Europe" rather than "produced in China," giving customers the impression that they are purchasing a higher-quality product. In one sense, the large number of designs demonstrates the capacity to accommodate practically all the fashion needs of clients of various ages, while in another sense, the young age of the designers demonstrates a flexibility of concept development. When compared to its rivals, this model's flexible nature and emphasis on customization set it apart (Fridley, 2018). Many of their competitors be contingent on a choice few creators to expect their industrial and enterprise difficulties. Because Headquarters organises ahead and sends just the forecast numbers, provisions have little say over whether items are shown or sold.

Many of the machineries used in staining, treating, and cutting the cloth were owned by Zara, giving the corporation more say over its ability to counter rapidly to unstable fashion trends. Because of this increased adaptability, Zara was able to reduce lead times and stockpiles. Designers draw the design draughts then deliberate it with marketplace specials and preparation & gaining staff, demonstrating a flexibility of idea group, and on the other hand, the massive number of projects imitates the capability to encounter nearly all the fashion necessities by clients of all ages. Unlike its rivals, this approach uses an adaptable model rather than conventional marketing.

Operational characteristics based on competitive priorities

Inventory, flexibility, and global reach are some of the operational characteristics of Zara in the retail industry. An increase in global reach allows the organization to expand its presence and influence in the international market. With an effective inventory level, the corporation can fulfill its competitive priorities as an increase in inventory allows Zara to fulfill the needs and demons of the customers (Gandrup and Li, 2020). Fulfilling the demands of the customers enhances the supply chain image of the business in the relevant market. Organizations in the retail industry are accelerating their competitive edge in the market by increasing the flexibility of deliveries and supply chain processes (Slack and Brandon-Jones, 2018).

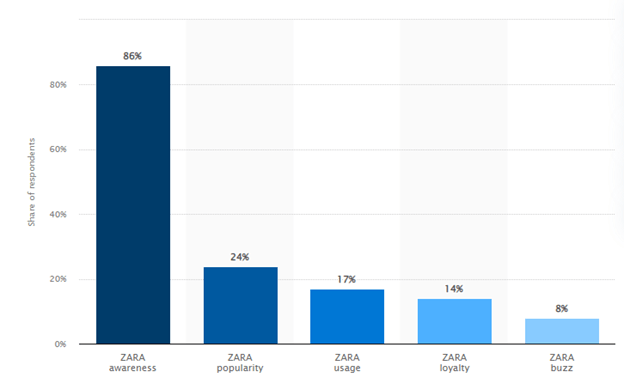

Figure 2: Brand awareness of Zara

The organization has implemented automation and advanced technologies to increase the effectiveness and flexibility of its supply chain process in the retail sector. The operational characteristic along with fulfilling the competitive priorities helps in increasing the value and influence of the product in the relevant market. Cost is also considered to be one of the characteristics of the operational process of Zara (Aftab et al., 2018). Implementing a proper cost of the products in the supply chain unit the organization is able to increase the demand for its products and services among the customers.

Business approach towards planning and controlling

The organization uses RFID technology for planning and controlling its supply chain operations. With RFID technology the corporation is able to track and trace the delivery of its product to the customers and clients. The planning and controlling of the resources are aligned with the allocation of resources and activities in ensuring that the operational process in the supply chain unit of the organization is efficient and is able to meet the needs and demands of the customers on time. SAP is software that allows the corporation to make effective planning and control of its activities in the supply chain units (Slack and Brandon-Jones, 2018). With the use of ERP systems and software, the enterprise is able to manage and plan the operations in a structured manner. The system allows the organization to plan the operations daily as per the convenience of labor and workers involved in the operational unit of the organization (Xuejie et al., 2019). The planning process in Zara accomplishes different purposes of the business. It helps in identifying and determining the cost, the level of resources, and the time frame required for the completion of each task and activity.

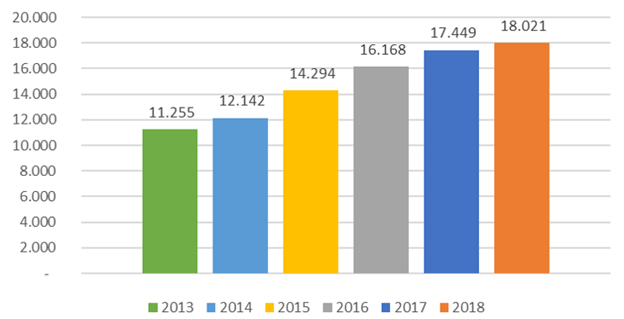

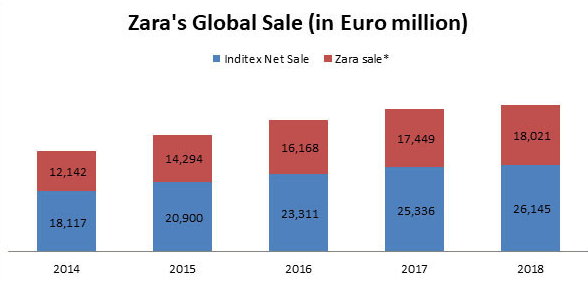

Figure 3: Net sales of Zara

Different from one another, control-oriented and involvement-oriented management styles of Zara use different ways of planning and managing. Both planning and decision-making power in a mechanistic organization rests with upper management, far from the operational level. Typically, the employees in the organization are only a passive actor in the planning and controlling process, acting as directed by the hierarchy and the object of the control activity. In an organic organization, employees are encouraged to take part in both the development and monitoring processes (Tien, 2019). As workers take on more responsibility for planning and managing, as well as carrying them out, management's function shifts to that of consultant, enabler, truth-seeker, educator, trainer, and giver of resources. When it comes to planning and regulating operations, higher-ups are held accountable, while lower-level workers are given the authority and obligation to do so on their own. When doing their duties of planning and controlling, upper-level managers often consult others farther down the organizational structure for insight. Finally, mechanistic firms tend to have sizable planning divisions and hire experts to oversee the planning process at the top level (Centobelli et al., 2020). Planning and controlling are moving closer to the point in the organization where the plans are executed and carried out on a daily basis as firms face increased ecological or equipment-encouraged ambiguity, fast environmental change, and turbulence. When putting organizational plans into effect, modern businesses depend less on top-down directives and more on professional staff and teams to regulate their own behavior.

Figure 4: Net sale of Zara

Business approachtowards planning and controlling also requires planning of inventories in the supply chain of Zara. Rather than manually counting each item, RFID devices provide a quick and accurate means of tracking their whereabouts. The use of RFID in tracking of inventory allows an accurate operational process in Zara. This allows the business in proper planning and controlling of further tasks and activities in the enterprise. RFID technology also helps in controlling the production of the goods and products in Zara.

Business approach towards transportation and logistics

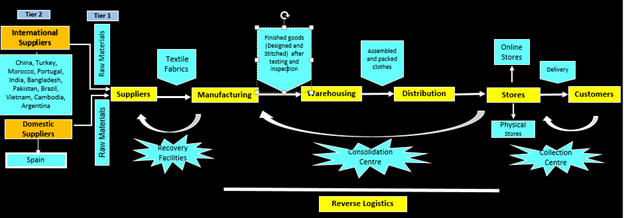

The organization uses third-party logistics for delivering its product to the customers. On the other hand, most of the deliveries of the organization are managed through the presence of in-house deliveries. Zara implements Toyota's "just-in-time" (JIT) logistical practices. Distributing the goods is likewise handled centrally, with Spain serving as a sorting hub from which retailers all around the globe get their supplies (Chopra and Meindl, 2000). However, "his" models, sizes, and colors are the ones distributed to stores. They are pre-ordered by the sales managers. New items are available in European retailers within 24 hours, and in the United States and Asia within 48 hours, thanks to a well-oiled distribution infrastructure (Slack, 2017). Without freight aviation, this rate of speed wouldn't have been possible. It's a hefty sum. However, the exclusivity felt by purchasers is enhanced when things are sold in tiny, quickly-moving batches.

Figure 5: Flow chart of Zara supply chain

Manufacturers for Zara are embedding garment tags directly into textiles as a time-saving measure, allowing for faster product delivery to the shops' final selling areas. Zara places a premium on speed in its outbound supply chain; domestic deliveries may be expected within 24 hours, and global distributions in 40 hours. The final objective is to accelerate the transition from creators to consumers.

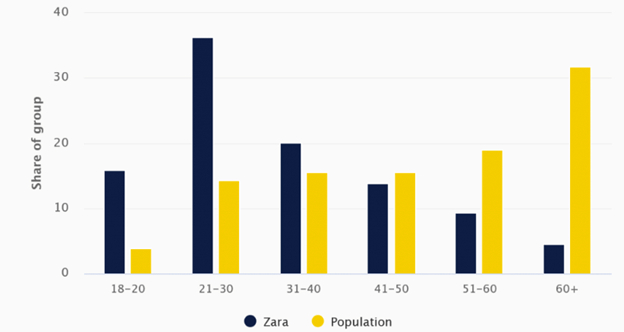

Figure 6: Zara target market

With centralised logistics, a retail chain may more easily manage the flow of goods from its suppliers to its many storefronts. Instead of having suppliers ship their goods to individual locations, they are instead sent to a single distribution hub. Zara's success may be attributed to the company's centralised structure. They act as a unified unit while making choices (Xuejie et al., 2019). It maintains a steady, quick, and deep beat that is centred on delivering orders to retail locations. Every Zara store is required to send in two weekly orders at certain times and days. There is a severe agenda in place for when automobiles depart and when distributions hit shelves. Clothes have their own tags and price tags at their final destination (Aftab et al., 2018). This regularity ensures that all departments (including design, procurement, manufacturing, distribution, and retail) are conscious of their characters and the limit for completing tasks. That undoubtedly includes Zara customers, who are well conscious of when to shop for the newest styles.

Zara has made significant investments in technology and logistics over the last six years, spending over two billion euros on these areas in an attempt to fortify the company's centralized production and distribution system, maximize efficiency, and reduce waste across the supply chain. Large technical systems that give real-time data are essential to the logistics industry of Zara as a whole. One of the biggest problems in retail is maintaining as much control as possible over inventories. The availability of interconnected businesses in all aspects of goods delivery and the automation of warehouse operations make it possible to maintain this consolidated system.In accordance with the third party logistics in the organization, Zara uses an invitation process of yearly bids from distinct international freight forwarders and transport organizations. The enterprises with lower bids are selected for building business with Zara. The third party providers are selected on the basis of their international networks and their capability in handling the shipments for Zara. Services such as vendor and supplier management, custom brokerage, distribution services are some of the facilities provided by the third party transport to the organization.

Business approach towards technology application within their operations

Artificial intelligence

Zara is known to be using one of the most powerful yet expensive software that is known as an RFID microchip which is attached to the clothes before they are leaving the central warehouse (Roederer and Mayrhofer, 2021). It helps in tracking the inventory up to the product that is sold in the market. The ID of the garment is recorded in the chip outside the security alarm (Slack and Brandon-Jones, 2019). Moreover, it helps in pinpointing the models and the size that needs replenishing when the shipment reaches the twice-weekly store.

Zara has opened a fully digitally improved store in a UK shopping complex under the "Pop-up Store," in addition to generating in-store experience retail using AI robots. The automation technology of Zara has provided fantastic extras like a mirror-integrated item suggestion system. Customers may scan their goods using Radio Frequency Identification at a mirror to get recommendations for complementary items in their size and style.

Digital Marketing

Stock management system and Omni channels are two marketing strategies that are used by Zara. Automate marketing stem are being used by Zara that helps in providing all the relevant information (Slack and Brandon-Jones, 2019). Thus, it helps the customer in understanding the brand in better manner.

Among the options available now, using social media is likely to provide the greatest results. Zara found it rather easy to join these communities. Overall, it has 52,000,000 Instagram followers, 30,000,000,000 Facebook likes, and 1,500,000 Twitter followers. Zara's social media presence is a strength of the company. Profiles show that consumers are conversant with the company and want to engage with it. The Galician firm has a wide audience for its content sharing. Via a well-executed inbound marketing plan, they are able to spread interest in their wares through the sharing of photographs and videos.

Data Analytics

Big data analytics are being used by Zara in getting the real time updates regarding the stocks.. Thus, it helps in increasing the customer satisfaction rate which has a strong impact on the rate of the sale (Slack and Brandon-Jones, 2019). The inventory is on a localized basis; it does match up to the requirement of the customers. Strong customer satisfaction has been witnessed which has helped in increasing the sale of the products. Most importantly, it helps in pushing the new inventory as per the demand of the customers. Using PDAs, RFID tags sewn into the apparel, POS terminals, and consumer questionnaires, ZARA compiles information about its online sales. Employees use handheld devices to record specific customer requests such as preferred style, size, color, number of pockets, and fastening method. According to the Wall Street Journal, RFID tags are the backbone of Zara's operation. This enables Zara to more efficiently manage inventory and track the garments that are coming and going from the store on a regular basis. Data is also gathered through surveys and Zara's social media channels. Because of their constant movement, they are aware of the changing tastes and requirements of their clientele. Data is aggregated at their Arteixo, Spain data center after being gathered from the aforementioned sources. The analysts analyze the data around the clock so that new designs can be released, products can be sent to retailers, and many other things may be done. Each week, Zara uses their massive database of sold items to make educated guesses about the next week's sales. Data analytics have helped Zara learn all there is to know about their clientele. This explains why it has become so well-liked.

For Zara, spotting a fashion trend early is ingrained in the company's ethos. The shops use a point-of-sale (POS) system, and the data collected is sent to Inditex. Zara's degree of responsiveness has increased thanks in part to the POS technology's facilitation of strengthened ties with suppliers and the resulting enhancements to the ordering procedure, the distribution network, and the delivery of merchandise. Also, managers often use PDAs to see whether any new designs are available, and if so, to make orders for products they believe would be well received by their clientele (Hoque, 2021). Managers of retail establishments help influence fashion by doing this. Zara's data and communication standards diverge significantly from those of its rivals. Less than half of one percent of income is allocated to IT, and even that little percentage doesn't even make up one percent of the workforce. Comparatively, their rivals allocate just approximately 2% of revenue to IT and 2.5% of employees to this sector. Zara has also spent much on its logistical system and developing its IT systems (Hoque, 2021). Zara avoided establishing any kind of bureaucratic structure by adopting a Just-In-Time (JIT) manufacturing method and investing in an advanced communications system that facilitates communication between the company's headquarters and its supply, production, and sales locations.

Recommendations

Zara requires to optimize their own inventory which will help in keeping a track of the record of their products. In terms of accessing and evaluating the KPI, the company should be adopting measurement process with technological integration. The retail fashion brand also requires to improve their supply chain management by introducing environmental sustainability. The brand needs to focus on establishing green initiates within the organization. The company also needs to improve its Omni channel strategies and market forecasting to ensure that the KPIs are utilized in optimized manner. Zara's primary issues of business approach may be addressed by two major suggestions. To begin, Zara may benefit from launching provincial delivery routes that would obtain items straight from industrial amenities rather than the three major delivery hubs in Spain. The planned course of action is to set up transport of possessions from European manufacturing amenities to provincial delivery hubs in North America and Asia. Second, Zara might increase its online sales by setting itself apart from its major rivals. To achieve this goal, the company should study its target market to identify the characteristics of an exclusive marketing proposition that would encourage more individuals to shop at its online shops. Next-day or same-day shipping, tailoring services, and free virtual appointments with a personal shopper are all offerings that set online apparel retailers apart from their brick-and-mortar counterparts. With these additions, Zara would be able to boost their online sales significantly.

Those two changes would help the company fix its most pressing issues with the brand. Delivery delays and inventory shortages might be avoided, for instance, by establishing regional distribution centres that are in close proximity to manufacturing plants. The convenience of online buying would be improved as a result of the shortened shipping times. Additionally, lowering transportation needs would help Zara achieve its environmental targets. Developing a distinguishing feature for Zara's online store has the potential to draw in more shoppers, leading to increased sales and ultimately, the company's expansion. Given Zara's present monetary standing, both components of the achievement strategy are doable, and the administration team will likely support of them because of the positive impact they will have on the business. It is clear that Zara has the capacity to execute them and that there will be no restrictions to execution given the scope of its present operations and its expertise in worldwide distribution and sales. Zara also needs to expand its internet presence. In the next few years, the online fashion retail business might be significantly disrupted by the likes of Shein, Yesstyle, Romwe, Princess Polly, and many more firms. When compared to its competitors, Zara's online shop is weak. Brand needs to inform the website to make it more user-friendly, both for new and frequent visitors. The present website places an extreme importance on graphic application, making it problematic for operators to glance the site and recognize the promoted goods due to the simple enterprise and disrupting model stances. The online shop has been criticized for its poor mobile compatibility and the difficulty of navigating its tabs, among other issues. 37% of visitors say they quit the site because of frustration with its design or navigation, leaving Zara susceptible to lost business.

It will take some time for the company's visual selling workforce to become used to the new e-commerce platforms it is releasing in an determination to upsurge online transactions. It might take a lot of determination to find suitable grouping and competition styles to construct shapes that are in accordance with actual customers' behaviors. Zara may use AI to boost its inclination locator, allowing it to stay ahead of competitors and newcomers to the ultra-fast approach market. To help guide online retailing photo shoots, cutting-advantage knowledge can classify and anticipate the most popular creation and product influences, as well as the most attractive enterprises, colors, and qualities.

By enhancing demand forecasting, AI may help close the "just-in-time" production gap. Over eighty-five percent of the company's annual output is made during the current season, rather than in anticipation of future fashion trends. The company may become more environmentally friendly and avoid the problem of overproduction that competitor H&M also confronts. Customers' wants and requirements may be predicted months in advance, giving the store time to work with designers on creating items that would sell well. The organization also needs to improve its logistics and transportation along with maintaining sustainability in the units. In doing so the enterprise needs to implement vehicles and transp;aorts that offer positive impacts on the environment. For example, using electric vehicles will help in reducing the emission of greenhouse gasses which will allow the business to offer positive images on the customers and the environment in different countries and regions.

Conclusion

The paper has emphasized that Zara requires them to concentrate on several aspects of supply chain management, in order to bring out the effectivity of the organizational functionality. The supply chain management of Zara must technologically integrated can provide satisfactory results in terms of profit maximization and resource utilization. It has been observed that Logistics and inventory management are also two different factors that the company needs to take concern for a better supply chain management. Overall, Zara is a successful international label with a solid financial footing. To succeed in today's cutthroat marketplace, however, the brand must do something fresh. Zara should implement the advised choices of enhancing delivery by founding local delivery hubs and increasing connected transactions capacity by emerging a characteristic marketing proposal. By applying these proposals, the company will be able to boost its net sales and profitability.

The Spanish clothing company Zara started in 1975 and has prolonged to become the utmost apparel brand in the world. The company's upright incorporation and value benefit allow it to control the fast-approach manufacturing, which it does by selling in stores and online all over the globe. As the industry as a whole continues to expand fast, Zara will need to effort hard to keep up with the opposition by honing its advertising approach, increasing its online occurrence, and preserving its commitment to ecological sustainability. It has been found that sustainability is one of the areas that the organization needs to focus on for developing and advancing its presence in the apparel market in different regions and countries. Using electric vehicles is one of the recommendations for Zara which will allow the organization to enhance its presence and increase its sales among customers. The findings also illustrate that Artificial Intelligence is another technological element that will help the organization in increasing its efficiency and pace in the retail market. The use of AI will also help the organization to mitigate its issues of over production in its operational process. On the other hand it is feasible and suitable for the organization to enhance its digital platforms for attracting more customers and clients for its business. Establishing a regional distribution center is another recommendation that has been presented in the report. The establishment of a regional center will allow the organization to tackle the issues of business approach towards the operational process.

References

Aftab, M.A., Yuanjian, Q., Kabir, N. and Barua, Z., 2018. Super responsive supply chain: The case of Spanish fast fashion retailer Inditex-Zara. International Journal of Business and Management, 13(5), p.212. Available at: https://d1wqtxts1xzle7.cloudfront.net/61061578/Zara_Case_Study20191029-42781-f73lj1-libre.pdf?1572387307=&response-content-disposition=inline%3B+file%3DSuper_Responsive_Supply_Chain_The_Case_o.pdf&Expires=1672400558&Signature=bLPZfpQh96QLiX4tBBSJENUFS8gNkh9YFZSJ1CvMGt~aja1jLazg7vXAuthai7dYZsu5Kmo6pQx-HokfffVpBrNbPKUqXExMiH9v~osPTbu71C4-1cgcbnj062kKdO994exqU8PABqli~fJW9q6X53M~PgCdsVIFU~0c6jS~Za0rm9bDAkA-m7b3A-nNamYYvqPR89UCK5jF4mAIRVpy8HD7b~6XhDcUiv6QlVJ5-OKfsLSu3uW1~zw-mQKUjxekjfoiU8oA26vi63xfkqzwSHzDCo6VZeewfx3qyDvmhAh12N3Yc5gSNNkkzgUciUtTmmcvoTMgRAmCHvkSD~aoNQ__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA (Accessed: 23 December 2022)

Centobelli, P., Cerchione, R., Chiaroni, D., Del Vecchio, P. and Urbinati, A., 2020. Designing business models in circular economy: A systematic literature review and research agenda. Business Strategy and the Environment, 29(4), pp.1734-1749. Avaialbale at: https://onlinelibrary.wiley.com/doi/abs/10.1002/bse.2466 (Accessed: 23 December 2022)

Chopra, S. and Meindl, P. (2000) Supply Chain Management: Strategy, Planning and Operation. Pearson. Available at: https://link.springer.com/chapter/10.1007/978-3-8349-9320-5_22 (Accessed: 24 December 2022)

Fridley, L., 2018. Improving online demand forecast using novel features in website data: a case study at Zara (Doctoral dissertation, Massachusetts Institute of Technology). Available at: https://dspace.mit.edu/handle/1721.1/117976 (Accessed: 24 December 2022)

Gandrup, J. and Li, J., 2020. Results from an Interrupted Time Series Study Gandrup, Julie; Li, Jing; Izadi, Zara; Gianfrancesco, Milena; Ellingsen, Torkell; Yazdany. Available at: https://findresearcher.sdu.dk/ws/portalfiles/portal/146799135/Three_Quality_Improvement_Initiatives_Improved_Performance_of_Rheumatoid_Arthritis_Disease_Activity_Measures_in_Electronic_Health_Records.pdf (Accessed: 24 December 2022)

Hoque, M.A., Rasiah, R., Furuoka, F. and Kumar, S., 2021. Technology adoption in the apparel industry: insight from literature review and research directions. Research Journal of Textile and Apparel. Available at: https://www.emerald.com/insight/content/doi/10.1108/RJTA-08-2020-0090/full/html (Accessed: 25 December 2022)

López, T., Riedler, T., Köhnen, H. and Fütterer, M., 2022. Digital value chain restructuring and labour process transformations in the fast‐fashion sector: Evidence from the value chains of Zara & H&M. Global Networks, 22(4), pp.684-700. Available at: https://onlinelibrary.wiley.com/doi/full/10.1111/glob.12353 (Accessed: 25 December 2022)

Roederer, C. and Mayrhofer, U., 2021. Zara: Managing the global supply chain successfully (No. halshs-03083454). Available at: https://ideas.repec.org/p/hal/journl/halshs-03083454.html (Accessed: 26 December 2022)

Slack, N. and Brandon-Jones, A., 2018. Operations and process management: principles and practice for strategic impact. Pearson UK. Available at: https://books.google.co.in/books?hl=en&lr=&id=vA5MDwAAQBAJ&oi=fnd&pg=PT11&dq=Slack,+N.+and+Brandon-Jones,+A.,+2018.+Operations+and+process+management:+principles+and+practice+for+strategic+impact.+Pearson+UK.&ots=F1ZGCCLn0d&sig=3Yd15Ff5rFhP_zKcsfaoipUbt1c&redir_esc=y#v=onepage&q=Slack%2C%20N.%20and%20Brandon-Jones%2C%20A.%2C%202018.%20Operations%20and%20process%20management%3A%20principles%20and%20practice%20for%20strategic%20impact.%20Pearson%20UK.&f=false (Accessed: 26 December 2022)

Slack, N., 2017. The Operations Advantage: A Practical Guide to Making Operations Work. Kogan Page Publishers. Available at: https://books.google.co.in/books?hl=en&lr=&id=ikiFDgAAQBAJ&oi=fnd&pg=PP1&dq=Slack,+N.,+2017.+The+Operations+Advantage:+A+Practical+Guide+to+Making+Operations+Work.+Kogan+Page+Publishers.&ots=GuXzFmABfC&sig=-m4-duEGYOcbgeoUp7BH1AN2yEc&redir_esc=y#v=onepage&q=Slack%2C%20N.%2C%202017.%20The%20Operations%20Advantage%3A%20A%20Practical%20Guide%20to%20Making%20Operations%20Work.%20Kogan%20Page%20Publishers.&f=false (Accessed: 26 December 2022)

Tien, N.H., 2019. International economics, business and management strategy. Dehli: Academic Publications. Available at: https://www.researchgate.net/publication/338570555_International_Economics_Business_and_Management_Strategy (Accessed: 26 December 2022)

Xuejie, C., Chang, Q. and GuangHao, Z., 2019, August. Research on Innovation supply chain Management in Fast Fashion Industry——A comparative analysis of ZARA and H&M. In 2019 3rd International Conference on Education, Culture and Social Development (ICECSD 2019) (pp. 7-16). Atlantis Press. Available at: https://www.atlantis-press.com/proceedings/icecsd-19/125916550 (Accessed: 26 December 2022)

Go Through the Best and FREE Case Studies Written by Our Academic Experts!

Native Assignment Help. (2026). Retrieved from:

https://www.nativeassignmenthelp.co.uk/analysis-of-the-supply-chain-of-zara-case-study-20804

Native Assignment Help, (2026),

https://www.nativeassignmenthelp.co.uk/analysis-of-the-supply-chain-of-zara-case-study-20804

Native Assignment Help (2026) [Online]. Retrieved from:

https://www.nativeassignmenthelp.co.uk/analysis-of-the-supply-chain-of-zara-case-study-20804

Native Assignment Help. (Native Assignment Help, 2026)

https://www.nativeassignmenthelp.co.uk/analysis-of-the-supply-chain-of-zara-case-study-20804

- FreeDownload - 1807 TimesImpact of Misinformation on Student Grades: A Research Case Study

Impact of Misinformation on Student Grades: A Research Are you in search of...View or download

- FreeDownload - 674 TimesIKEA Marketing Strategy in the UK - Brand Analysis & Future Outlook - Case Study

Principles Of Marketing in the UK Explore unparalleled assignment writing...View or download

- FreeDownload - 1332 TimesMac Donald's Business Case Study

Mac Donald’s Business Case Study Introduction - Mac Donald’s...View or download

- FreeDownload - 1372 TimesBurj Khalifa Construction: Digital Technologies and Project Management Case Study

Burj Khalifa Construction: Digital Technologies and Project Management Enhance...View or download

- FreeDownload - 1008 TimesMG414: A Detailed Case Study on Organisational Behaviour

Introduction: MG414: Organisational Behaviour Through secondary research,...View or download

- FreeDownload - 789 TimesThree Theories Of Banking And The Conclusive Evidence By Richard

Three Theories Of Banking And The Conclusive Evidence By Richard A....View or download

-

100% Confidential

Your personal details and order information are kept completely private with our strict confidentiality policy.

-

On-Time Delivery

Receive your assignment exactly within the promised deadline—no delays, ever.

-

Native British Writers

Get your work crafted by highly-skilled native UK writers with strong academic expertise.

-

A+ Quality Assignments

We deliver top-notch, well-researched, and perfectly structured assignments to help you secure the highest grades.