Burj Khalifa Construction: Digital Technologies and Project Management Case Study

Burj Khalifa: Constructing the World's Tallest Skyscraper by Native Assignment Help

Ph.D. Experts For Best Assistance

Plagiarism Free Content

AI Free Content

Burj Khalifa Construction: Digital Technologies and Project Management

Enhance your academic journey with specialized assignment help services from our trusted professionals.

1. Introduction: Burj Khalifa: Constructing the World's Tallest Skyscraper

The Burj Khalifa, the tallest skyscraper in the entire world, is located in Dubai. The skyscraper was started to construct in 2004 and because of some issues, it took 5 years to complete its construction. The world's tallest skyscraper was completed in 2009. This skyscraper was built by the Emaar Properties in Dubai which have several other companies. This building was designed by several other companies such as Skidmore, Merrill Architecture Chicago, and Owings. Due to the indefectibility of some factors and technologies, the world's tallest skyscraper took a lot of time to complete construction. In this report, the issues of this construction delay have been discussed. In addition to this, the proper use of digital technology and its use have also been evaluated in the report for better further development of these kinds of construction projects.

Construction projects are generally found critical due to the complex structure of project management. The construction of Burj Khalifa provided a very critical aspect of the contribution to greenhouse gas emissions. This has been found that the construction of the Burj Khalifa project was found to be very precise and environmentally friendly which is why there was a lot of scope for the reduction of pollution. In this essay, different uses of technology, especially BIM on digital construction are the main themes.

Thesis statement: Digital construction has been found to be very effective and precise in the constriction of Burj Khalifa.

2. Reason for project delay

2.1 Factors of delaying the construction project

There are mainly 4 different factors that have affected the construction delay of Burj Khalifa. One of the most significant factors in the construction delay of Burj Khalifa was improper environmental conditions and post-execution phase management. It has been found that the building was in Dubai where the temperature is extreme. Hence the building had to face and withstand tremendous heat. In the summer, the temperature near Burj Khalifa reached almost 50 degrees Celsius. As per the view of Suresh and Nathan (2020), this was a very critical issue because the employees and workers were not able to work in the summer. Due to this issue, employees were to take a lot of recess breaks at this time. The critical problem came around when the construction team had to create an exterior cladding that was made of reflective glazing with aluminum and textured stainless steel. In addition to this, 26000 glass panels also needed to be created to prevent extreme heat conditions during summer. This included more time to make those panels.

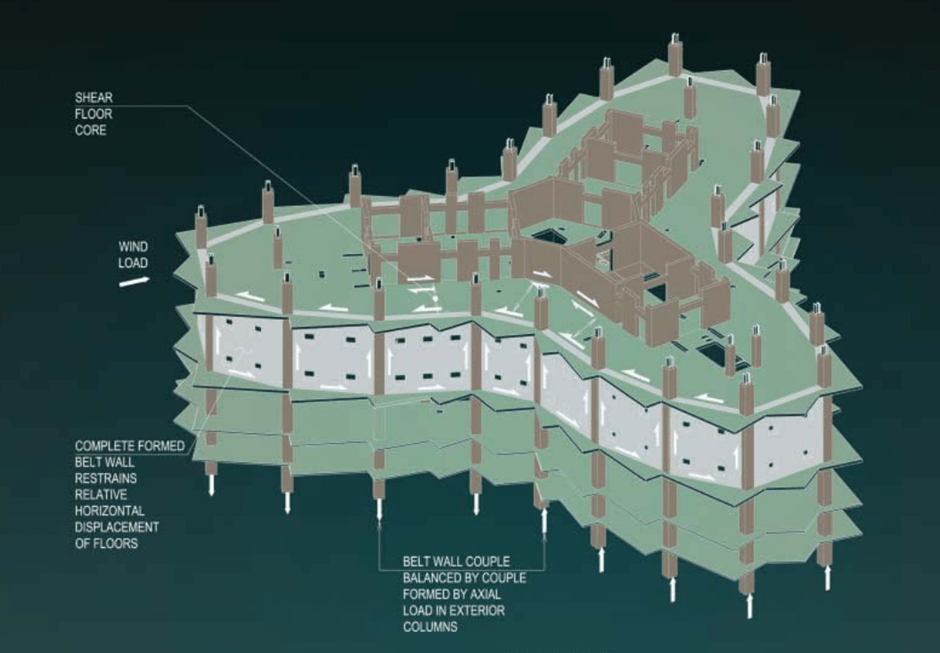

Figure 1: Y-shaped tripartite floor geometry

The second factor in the delay of this project's construction was the complexity of the design itself. Based on the comments of Zarei et al. (2018), the construction of the building was planned to be the world's tallest construction project. Another reason for this complexity was the "Y-shaped tripartite floor geometry” which was a completely innovative approach for the engineers so that residential and hotel places could be optimized.

Improper project scheduling is another factor that has resulted in the project delay. This project schedule was started in January 2004. After that due to some scheduling error, the construction was delayed for one year before starting the superstructure. Due to construction and project management risks, it took almost 2 years and 4 months to reach reconstruction of 50 levels. As opined by Gebrehiwet. and Luo (2018), this was almost 8 months behind the target. The entire construction of the 160 levels was completed in April 2008 which was almost more than 1.6 months behind the project schedule. After that, the compilation of the spire took more than 8 months which was to be done in 6 months. Hence, these were the issues of the delay of the project.

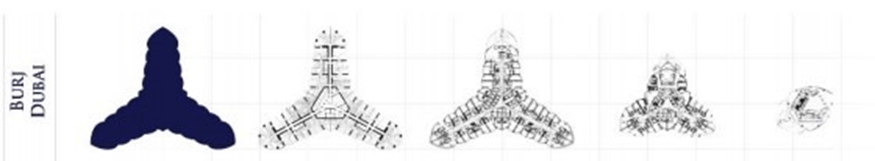

Figure 2: Cross-section plan

Another reason that the construction of the tallest skyscraper was delayed was the wrong engineering estimations by the construction engineers. As per the comments of Sanni-Anibire et al. (2022), it resulted in the development of construction delays because of the weight of ice used for construction purposes. Also, most of the construction work was done at night during summer to avoid the extreme heat. One of the most innovative approaches by the engineers was found when they had to mix the concrete with a huge amount of ice so that the construction and concrete efficiency could be increased.

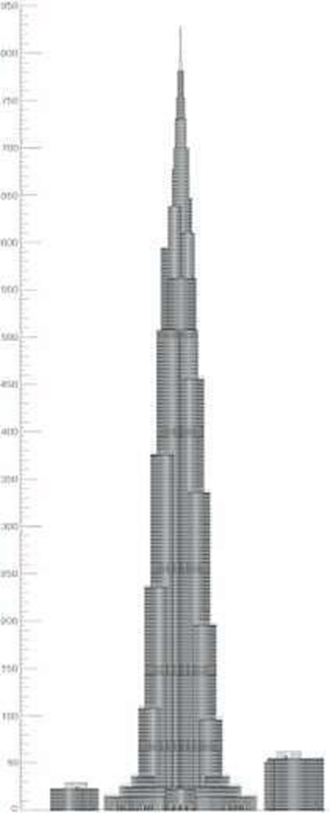

Figure 3: 40 wind tunnel architecture

For the construction of the entire building, 40 wind tunnel tests were used for construction purposes and pouring the ice-mixed concrete in those tunnels. The cooled mixture was also appropriate and less likely to crack. Aluminium-based surpasses were also found to be very heavy which was not estimated by the engineers. Based on the opinion of Yap et al. (2021), this issue of construction delay was also estimated to create some specifications of the weight of almost five A380 aircraft. The construction also demanded a series of cranes which required more engineering intelligence and technical guidance.

2.2 Usefulness of project planning to mitigate the delay in the near future

In current times there are a lot of construction technologies available that are capable of avoiding these issues. Proper project planning for any construction project like Burj Khalifa can clear the objectives. From the viewpoint of Mittal et al. (2020), this includes the estimation of the time funding, and resources required in any construction project. In the future, project planning might use some tools of the project and financial estimation. The construction project of Burj Khalifa was done wrong and it took more time and money to complete the entire construction project. Based on the analysis of Amri and Marey-Pérez (2020), it was observed that construction project planning in the future will be focused on time and resource allocation. Project planning will help the construction projects to hit the milestones properly.

The chance and risk management can get better with effectively estimated management clarification. According to the statement of Bjorvatn and Wald (2018), the construction of Burj Khalifa was generally extended because of some significant risks and these risks could not be managed to save money and time.

Proper project planning initiates and boosts project performance. As opined by Sakib et al. (2021), this benefit will also be reflected in the construction of future projects. Hence, a proper project-driven performance will be found in all types of construction cases in future. As per the thoughts of Yahya et al. (2019), proper risk management will help the construction team to identify the possible risks and take effective steps to mitigate those constitutional risks as well.

3. Use of different technologies in the construction of Burj Khalifa

The construction or the design of the skyscraper was based on the innovative “V-Stick" technology. The Hymenocallis flower was the main inspiration for this technology. In the construction of the Burj Khalifa, several technical advancements were also available.

Out of these, “Geotechnical technology" is one of the most basic technologies that assisted the construction of the skyscraper. Based on the view of Alizadehsalehi and Yitmen (2020), this was evident that the world's tallest skyscraper was to be built in a specified, and proper geological condition, this was the reason that proper two years of groundwork was done with this geotechnical technology. Proper geotechnical investigation and testing were done for the foundation of the construction. The building footprint and weak soil condition checking for handling excessive load were done. This is why a 3.7-meter thick raft foundation was done along with 192 bored piles with this geotechnical technology.

Another technology was “Concrete Pumping technology" which assisted in providing a pumping process to more than 600 metres. As per the opinion of Gharbia et al. (2020), this was not done previously and a string of concrete pumps with high pressure was used in this technology. This technology was also the reason for getting a world record of pumping concrete to 601 metres which was done in the construction of Burj Khalifa for the first time. For more than 30 months, this high-pressure concrete pump was used to pump more than 165000 cubic meters of high-strength concrete with this technology. There were almost 66 Olympic-sized swimming pools. This pumping was done by mixing ice with the concrete and the operation was done at night of extreme heat during the day.

“Wall and Floor Technology” is another technology that was used in the construction of floor and wall construction of the building. The structural system of the building can be considered as a buttressed core. Based on the opinion of Yang et al. (2019), the walls and floors of each wing were created with perimeter columns and concrete corridor walls were created through a hexagonal hub. "Information and Communication Technology" or ICT was also used for the construction of the Burj Khalifa. It was discovered that there are basically 4 tools that were used in the construction. These are telephone, radio, television, and internet. The use of ICT tools includes the application of IT software and tools in several construction sectors like communication, designing, and managing infrastructure. This technology was also used for the administrative purposes of the construction of Burj Khalifa.

It has been found that ICT tools help the construction team to perform complex tasks easily. Time and cost saving was the main objective of using ICT technology in construction. "External Wall technology" was also another technology that assisted the innovative wall construction. The main significance of this technology was to implement a "two-paned window" system specially designed for the Burj Khalifa construction. From the viewpoint of Xu and de Soto (2020), the external glasses were used to reflect the daily solar heat because the external glasses were coated with a thin metal layer. This deflects the ultraviolet radiation from the sun. For external walls, there were two layers used. The external layer was the first plane which cannot reflect the infrared radiation from the sun. This is the reason that the inner pane was coated with silver so that the infrared rays could be reflected out.

The “Auto-id technology" is another technological advancement that was used in the construction project. This technology is nothing but automatic identification technology which is an AI-based technology. This technology was used in the construction for completing automatic data identification. Based on the analysis of Zima et al. (2020), this technology was used for identifying different objects at the construction site host and capturing data from the constriction database. One example of this technology is the "barcode system". This technology can use the bridging method in delivering physical data with digital data. The "Radio frequency identification (RFID)" technology is also an example of auto-id technology that was used in the Burj Khalifa project. This technology helps to improve the quality of the construction and identify mistakes. In the Burj Khalifa project, this technology was used to identify human errors. The Auto ID tool also helped the construction team to enable the safety precaution system which is why there was only 1 death reported during the entire project lifecycle. This was the reason that the project is considered to be one of the most successful projects of all time.

4. Usefulness of BIM technology in the construction of Burj Khalifa

“Building Information Modelling" or BIM is a recently developed technology that might be used in the construction of technological advancements for technical assistance. This technology was not used in the construction of the concerned project. According to the statement of Mandičák et al. (2021), this technology initiates cooperative planning and execution for the management of construction purposes. The use of 3D modeling technology and record tracking is included in this innovation and software advancement.

This technology might help the project management team of Burj Khalifa to increase efficiency and manage the time of delivering the project properly. BIM might be used by the engineers to ensure the data-capturing process with the progress of construction and create operation and maintenance activities. The project management team might use this technology to initiate online and onsite collaboration and communication. From the viewpoint of Song et al. (2019), BIM technology might be used most effectively in cost estimation. The Burj Khalifa construction was done at a very high cost and time. Both of the issues might be solved with BIM technology. BIM technology can improve access to information which is why a better supply chain management (SCM) can be constructed. BIM connects with the supply chain management technology that relates to the previous and isolated data on any construction project. Hence, better organizational agility can be observed in SCM networks.

Better coordination and clash detection might also be performed with this BIM technology. It is evident that BIM technology could resolve risk management and cost management properly. Hence, proper cost estimation and resource allocation might be possible. Based on the opinion of Leśniak et al. (2020), the model-based system might help the project management team in managing risk and reducing costs. As discussed before, BIM technology is very impactful for involving better collaborating which is why a lot of other digital innovations can influence the SCM of the construction project as well. Therefore, the logistics and delivery-related issues will not happen in any construction. BIM technology can also help in improving scheduling processes. This feature of BIM technology might help the construction in managing the task dependencies and meeting the deadline. Hence, proper time management can be done with this technology. The improvement of productivity rate might also be increased with this technology.

5. Construction project planning and management

5.1 Possible constraints

There is a significant relationship between project leading and managing the team and resources. The project leading in the construction project might be one of the most effective approaches that managing the entire human resources to manage the resources and cost of the construction. It is identified that the construction project might need proper assistance and management solutions to complete the project. As per the comments of Al-Ashmori et al. (2019), it was evident that the construction project leadership might face the constraints of cost. While delivering the project, the cost cannot be managed as per the estimation. It was estimated that the construction of the project would be completed within $900 million USD. After the project delay of more than 9 months, it was quite a shock that it took $1.5 billion USD to complete the project which was $600 million USD more than the expected cost.

The quality of the project and the construction of the Burj Khalifa could be another possible constraint. The reason for this selection is that the project was created to construct the world's tallest skyscraper with a huge amount of cost enhancements. Due to a lot of time delays for the project management team, it was possible for the construction team to provide poor quality to meet deadlines and save as much money as possible. In this case, proper time and finance estimation were possible but it would decrease the quality of the construction of the project. Time could be another constraint in the construction of Burj Khalifa. Before the construction, it was expected to complete the project within 5.3 years. Due to several issues and financial and managerial risks, the construction of the project took more than 9 more months. This was the reason for estimating this as a project constraint.

5.2 Use of BIM technology in construction execution

In order to help in the construction execution, BIM technology is the most effective and appropriate technology. As per the thoughts of Xiao and Bhola (2022), this technology is capable of delivering online collaboration and communication which is one of the primary requirements within the construction sector. More project efficiency can be gained with the technology. From the opinion of Liu et al. (2018), this system of estimating the cost is also known as the 5D BIM system. The factors with higher values as well as lower values are also estimated in this system such as factoring risks and identifying construction assemblies.

Clash detection has become more accurate in construction projects. With the assistance of "Autodesk’s BIM 360 Glue", all the time, resource, and cost clashes can be avoided. Most companies (75%) use this technology to reduce the cost of the project through proper time management. This has become possible because of "construction schedule setbacks''. Based on the opinion of Mesároš et al (2020), construction hazards can also be avoided with BIM technology involvement. Another advantage of BIM technology includes the streamlined facility with real-time problem solving through "reality capture technology".

6. Conclusion and Recommendation

Recommendation

It has been found that BIM technology is a completely innovative and new technology that was not applied to the Burj Khalifa construction project. This technology should be used because this provides effective and appropriate technical assistance. BIM technology should also be used for visualizing the future performance of the project in the pre-construction stages. Different cloud-based tools such as "Autodesk’s BIM 360" should be installed within the project communication system of any construction site which will monitor, control, and seamlessly guide the project in a proper direction. BIM technology is also capable of delivering a 3D visualisation which is a type of augmented reality version. This is the reason that BIM is recommended to be applied to assist the designing and progress phase efficiently.

Conclusion

The Burj Khalifa construction is considered one of the most successful construction projects in spite of its excess cost and more time for complete. The construction took more than 9 months to be completed and almost $600 million USD more than was estimated. In spite of that, the project was a grand success because of the quality and presentation of the construction. However, the excessive cost and time of the project were the main opponents of this construction. There were several construction technologies used in Thai construction which are provided in the report. However, out of all those technologies, Building Information Modelling (BIM) may be identified to be the most effective and appropriate technology.

References

Al-Ashmori, Y.Y., Othman, I., Rahmawati, Y., Amran, Y.M., Sabah, S.A., Rafindadi, A.D.U. and Mikić, M., 2020. BIM benefits and its influence on the BIM implementation in Malaysia. Ain Shams Engineering Journal, 11(4), pp.1013-1019.

Alizadehsalehi, S. and Yitmen, I., 2019. A concept for automated construction progress monitoring: technologies adoption for benchmarking project performance control. Arabian Journal for Science and Engineering, 44(5), pp.4993-5008.

Amri, T. and Marey-Pérez, M., 2020. Towards a sustainable construction industry: Delays and cost overrun causes in construction projects of Oman. Journal of Project Management, 5(2), pp.87-102.

Bjorvatn, T. and Wald, A., 2018. Project complexity and team-level absorptive capacity as drivers of project management performance. International Journal of Project Management, 36(6), pp.876-888.

Gebrehiwet, T. and Luo, H., 2018. Risk level evaluation on construction project lifecycle using fuzzy comprehensive evaluation and TOPSIS. Symmetry, 11(1), p.12.

Gharbia, M., Chang-Richards, A., Lu, Y., Zhong, R.Y. and Li, H., 2020. Robotic technologies for on-site building construction: A systematic review. Journal of Building Engineering, 32, p.101584.

Leśniak, A., Górka, M. and Skrzypczak, I., 2021. Barriers to BIM implementation in architecture, construction, and engineering projects—The polish study. Energies, 14(8), p.2090.

Liu, D., Jin, Z. and Gambatese, J., 2020. Scenarios for integrating IPS–IMU system with BIM technology in construction safety control. Practice Periodical on Structural Design and Construction, 25(1), p.501-900.

Mandičák, T., Mésároš, P., Behún, M. and Behúnová, A., 2020. Development of Digital and Managerial Competencies and BIM Technology Skills in Construction Project Management. In New Approaches in Management of Smart Manufacturing Systems (pp. 159-175). Springer, Cham.

Mesároš, P., Mandičák, T. and Behúnová, A., 2020. Use of BIM technology and impact on productivity in construction project management. Wireless networks, pp.1-8.

Mittal, Y.K., Paul, V.K., Rostami, A., Riley, M. and Sawhney, A., 2020. Delay factors in construction of healthcare infrastructure projects: a comparison amongst developing countries. Asian Journal of Civil Engineering, 21(4), pp.649-661.

Sakib, N., Bhasin, A., Islam, M.K., Khan, K. and Khan, M.I., 2021. A review of the evolution of technologies to use sulphur as a pavement construction material. International Journal of Pavement Engineering, 22(3), pp.392-403.

Sanni-Anibire, M.O., Zin, R.M. and Olatunji, S.O., 2022. Machine learning model for delay risk assessment in tall building projects. International Journal of Construction Management, 22(11), pp.2134-2143.

Song, Z., Shi, G., Wang, J., Wei, H., Wang, T. and Zhou, G., 2019. Research on management and application of tunnel engineering based on BIM technology. Journal of Civil Engineering and Management, 25(8), pp.785-797.

Suresh, M. and Nathan, R.A.R., 2020. Readiness for lean procurement in construction projects. Construction Innovation, 20(4), pp.587-608.

Xiao, Y. and Bhola, J., 2022. Design and optimization of prefabricated building system based on BIM technology. International Journal of System Assurance Engineering and Management, 13(1), pp.111-120.

Xu, X. and de Soto, B.G., 2020. On-site autonomous construction robots: A review of research areas, technologies, and suggestions for advancement. In ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction (Vol. 37, pp. 385-392). IAARC Publications.

Yahya, M.Y.B., Hui, Y.L., Yassin, A.B.M., Omar, R., anak Robin, R.O. and Kasim, N., 2019. The challenges of the implementation of construction robotics technologies in construction. In MATEC Web of Conferences (Vol. 266, p. 05012). EDP Sciences.

Yang, Y., Pan, M. and Pan, W., 2019. ‘Co-evolution through interaction innovative building technologies: The case of modular integrated construction and robotics. Automation in Construction, 107, p.102932.

Yap, J.B.H., Goay, P.L., Woon, Y.B. and Skitmore, M., 2021. Revisiting critical delay factors for construction: Analysing projects in Malaysia. Alexandria Engineering Journal, 60(1), pp.1717-1729.

Zarei, B., Sharifi, H. and Chaghouee, Y., 2018. Delay causes analysis in complex construction projects: a semantic network analysis approach. Production Planning & Control, 29(1), pp.29-40.

Zima, K., Plebankiewicz, E. and Wieczorek, D., 2020. A SWOT analysis of the use of BIM technology in the Polish construction industry. Buildings, 10(1), p.16.

Go Through the Best and FREE Case Studies Written by Our Academic Experts!

Native Assignment Help. (2026). Retrieved from:

https://www.nativeassignmenthelp.co.uk/digital-construction-and-bim-case-study-17883

Native Assignment Help, (2026),

https://www.nativeassignmenthelp.co.uk/digital-construction-and-bim-case-study-17883

Native Assignment Help (2026) [Online]. Retrieved from:

https://www.nativeassignmenthelp.co.uk/digital-construction-and-bim-case-study-17883

Native Assignment Help. (Native Assignment Help, 2026)

https://www.nativeassignmenthelp.co.uk/digital-construction-and-bim-case-study-17883

- FreeDownload - 1381 TimesBusiness Report And Reflection - Brewdog

Task A 1. Introduction of Business Report And Reflection: Brewdog The report...View or download

- FreeDownload - 820 TimesComprehensive Case Study on Public Health Risks in Canada

Introduction Tuberculosis (TB) is an infectious disease by the Mycobacterium...View or download

- FreeDownload - 1655 TimesEvaluating Organisational Culture and Leadership at TUI: Strategies for Effective Change Management Case Study

Evaluating Organisational Culture and Leadership at TUI: Strategies for...View or download

- FreeDownload - 3101 TimesEmployee Retention As An Challenge For Human Resource Management-A Case Of Tesco Plc

Employee Retention As An Challenge For Human Resource Management-A Case Of...View or download

- FreeDownload - 865 TimesAnalysis of Unilever Business Strategy Assignment Sample

Introduction: Unilever's Strategy Analysis Assignment Research Background and...View or download

- FreeDownload - 789 Times5MARK006: Exploring The Contrasting Approaches Of Zara And Louis Vuitton Case Study

5MARK006: Exploring the Contrasting Approaches of Zara and Louis...View or download

-

100% Confidential

Your personal details and order information are kept completely private with our strict confidentiality policy.

-

On-Time Delivery

Receive your assignment exactly within the promised deadline—no delays, ever.

-

Native British Writers

Get your work crafted by highly-skilled native UK writers with strong academic expertise.

-

A+ Quality Assignments

We deliver top-notch, well-researched, and perfectly structured assignments to help you secure the highest grades.