CMA4004 Operation And Resource Management Assignment Sample

Introduction

The construction industry constantly changes, depending on organised human resource management and resource planning to deliver successful projects (Anwar and Abdullah, 2021). The effective management of human and physical resources is a fundamental factor in providing construction projects correctly, on time, and within budget while meeting needed quality requirements. The Assistant Project Manager role at this well-established construction company requires implementing contemporary management approaches to sustain operational excellence while upholding project delivery standards.

This research investigates all essential human resource and people management aspects in construction projects through workforce planning analyses, recruitment methods, team organisation practices, and employment law enforcement rules from the Equality Act 2010. This section evaluates welfare facilities as essential elements that boost workforce productivity levels. The report will analyse the base contrasts between project resource management and business resource management to assign suitable personnel to essential project roles during each developmental point. This report dedicates a critical section to presenting an effective process of scheduling and planning construction resources. Physical resources, including machinery, equipment, materials, and supply chain management strategies, will be detailed to achieve cost-effectiveness and prompt project completion.

The report analyses theoretical and practical resource management aspects through workforce development strategies, resource levelling techniques, and necessary planning and scheduling procedures. This document discusses how modern human resource management views workforce personnel as valuable organisational assets.

Human Resource and People Management

Definition and Impact of 4Rights

Human Resource Management (HRM) in construction performs strategic workforce planning while recruiting and managing personnel to achieve project success (Teo et al., 2022). The primary responsibility of HRM is to maintain an adequately skilled workforce with high workplace motivation and project goal alignment.

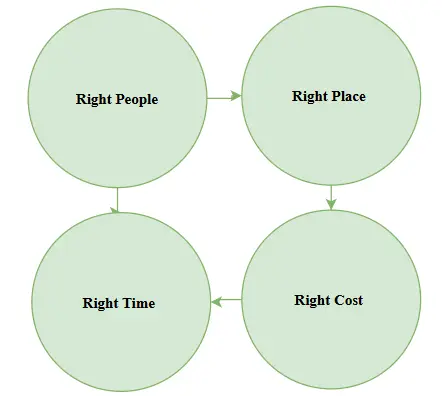

Successful resource allocation in this project requires following the 4Rights framework, which has four elements: the right people, the right place, the right time, and the right cost (McEwan et al., 2025).

Figure 1: 4Rights framework

(Source: self-developed)

- Right People – Ensuring that skilled labourers, engineers, and managers with relevant expertise are hired.

- Right Place – Deploying workers to the appropriate sites based on project demands.

- Right Time – Scheduling work shifts and construction activities to meet deadlines.

- Right Cost – Managing workforce costs to align with project budgets.

The successful application of 4Rights operational methods controls project schedule delays and construction expenses while upholding worker effectiveness for the apartment block development.

Project vs. Business Resource Management

|

Aspect |

Project Resource Management |

Business Resource Management |

|

Scope |

Focuses on managing resources for a specific project. |

Manages resources across multiple projects or business operations. |

|

Timeframe |

Temporary and ends when the project is completed. |

Ongoing and focuses on long-term business sustainability. |

|

Flexibility |

Requires rapid adjustments based on project needs. |

More structured, with long-term resource planning. |

|

Budgeting |

Budget is specific to the project and must be managed within it. |

Budgets are managed at the company level. |

Team Acquisition Process

To acquire a construction project team, it is necessary to have a structured approach to have available people who are skilled professionals or labourers in order to complete the project as per the expectations in conditions of time and quality (Rhodes and Bell, 2021). Workforce planning and job analysis are the first part of the process through which the project manager tabulates how many workers are needed at each phase of the project and what skill sets each one should possess. This step involves looking at project complexity, time, and expertise, i.e., the needs of surveyors, engineers, and technical staff.

Based on workforce planning, recruitment and selection processes are initiated (Jamal et al., 2021). There are different ways construction companies acquire personnel; they are employers who directly employ, contract and recruit through agency or apprenticeship programs. Hiring people directly, such as full-time staff, ensures stability and consistency from the start to the end of the project (Shestakofsky, 2024). This allows the company to employ specialized firms for specific tasks, such as electrical and plumbing work. By offering more flexibility in representation with this kind of recruitment agency, there is the opportunity to source temporary workers when demand is high, and apprenticeship programs support workforce development through trainees and graduate engineers.

Selection criteria are used based on experience, qualifications, health and safety compliance, and availability (Khalid, Sagoo and Benachir, 2021). To ensure conformity with the industry standards, the worker must be equipped with the technical expertise and certificates such as the Construction Skill Certification Scheme, CSCS. It also is crucial to ensure that workers are there when the project is scheduled in the phases.

Roles and Responsibilities in Construction Projects

|

Role |

Responsibilities |

Project Stage |

|

Project Manager |

Oversees planning, execution, and overall progress. |

All Stages |

|

Site Supervisor |

Ensures daily site operations and compliance with safety regulations. |

Execution |

|

Engineers (Structural, Civil, Electrical, Mechanical) |

Design and supervise construction based on technical specifications. |

Planning & Execution |

|

Quantity Surveyor |

Manages project costs and budgets. |

Planning & Execution |

|

Health & Safety Officer |

Ensures workplace safety and compliance with regulations. |

Execution |

|

Skilled Workers (Carpenters, Electricians, Plumbers, etc.) |

Carry out specialized construction tasks. |

Execution |

|

General Laborers |

Assist skilled workers and handle material transportation. |

Execution |

Welfare Facilities and Workforce Productivity

Construction projects feature welfare facilities that help to improve workforce productivity (Assaad and El-adaway, 2021). Facilities for workers are effective in enhancing morale, reducing absenteeism and, compliance with UK Health and Safety Executive (HSE) regulations. Toilets, washing facilities, rest areas, canteens, changing rooms, and first aid stations are essential welfare provisions (Rajan, 2022).

Construction sites are a legal requirement with specific ratios for sanitary facilities, depending on the number of workers. However, according to the HSE, there must be at least one toilet for every seven workers, up to 50 people, but for larger teams, there must be one toilet for every ten workers (HSE, 2015). There should also be enough washing stations, including for those who work in high-exposure work e.g. chemicals and wet trades. Hygiene-related illnesses can be prevented when clean and accessible sanitation facilities are ensured.

Productivity gain may come from rest areas and canteens where workers can take breaks in an atmosphere that is not on the road. Construction is a physically demanding field, and the workers need rest spaces to recover from the physically intense tasks they undertake to avoid becoming fatigued and consequently prone to accidents due to fatigue (Pamidimukkala and Kermanshachi, 2021). Serving nutritious food by canteens helps maintain energy at work place and prevents health-related absenteeism from enhancing workforce efficiency.

Workers have secure changing rooms and lockers to put personal possessions and swap into work clothing (Lin, Chiu and Chou, 2025). This lack of facilities can result in inefficiencies as workers have the time to waste searching for suitable spaces to change. It helps in building a certain kind of professionalism and orderliness on the construction site by providing well-maintained changing rooms for the workers.

Equality Act 2010: Protected Characteristics and Anti-Discrimination Policies

The Equality Act 2010 protects workers from discrimination based on the following:

- Age

- Disability

- Gender reassignment

- Marriage and civil partnership

- Pregnancy and maternity

- Race

- Religion or belief

- Sex

- Sexual orientation

Planning and Scheduling of Physical Resources

Physical Resources Required at Different Project Stages

|

Category |

Resource |

Function |

|

Transportation |

Trucks, Dumpers, Concrete Transit Mixers |

Transport raw materials such as sand, cement, bricks, and gravel to the construction site. |

|

Excavation |

Excavators, Backhoe Loaders, Bulldozers |

Dig the foundation trenches and clear debris from the site. |

|

Lifting |

Tower Cranes, Mobile Cranes, Forklifts |

Hoist heavy materials like steel beams, precast concrete, and roofing trusses to elevated levels. |

|

Foundation Work |

Concrete Mixers, Vibrators, Piling Rigs |

Prepare and pour concrete for the strip foundation and ensure uniform compaction. |

|

Structural Work |

Reinforcement Cutters, Welding Machines, Scaffolding |

Install steel reinforcements, weld structural components, and provide temporary working platforms. |

|

Finishing |

Plastering Machines, Paint Sprayers, Tile Cutters |

Apply plaster, paint, and install flooring and wall finishes. |

Construction Resource Scheduling Techniques

Construction resource scheduling techniques are to be used to keep the workflow smooth (Shah and Chandragade, 2022). A Gantt chart is a visual guide that displays when a certain task is to be completed and when a particular resource will be needed from the planners. The critical path method (CPM) is an approach that determines the critical activities that have to be executed on time by a project to avoid delays in overall project completion (Jaśkowski, Biruk and Krzemiński, 2021). Resource levelling helps adjust workloads to avoid over-allocation or underutilization of labour and equipment. Through the just-in-time delivery method, storage cost and material wastage is reduced to the minimum as materials arrive precisely at the right time as needed by each project phase (Amer and Golparvar-Fard, 2021). These scheduling techniques are used by construction managers to maximise resource allocation and to optimize the construction process.

Supply Chain Management in Construction

It will be imperative that construction materials, machinery and equipment are delivered to the site in a timely and cost-efficient manner. Stages included in the supply chain process of this project include supplier selection and procurement (Saputro, Figueira and Almada-Lobo, 2022). Production of quality products largely depends on the choice of reliable suppliers of raw materials like cement, steel, and bricks, among others. To prevent shortages, which could cause delays, the procurement process must consider the cost, quality and lead time (Marzouk and Sabbah, 2021).

Once suppliers are determined, logistics and transportation are crucial in getting materials to the project site in time. Logistics management is efficient when it involves coordination with the trucking companies and monitoring the material deliveries to ensure no sudden interruption (Hrušovský et al., 2021). The second important aspect of supply chain coordination is on-site inventory management. Storage facilities, whether for material wastage or theft, must be proper, and an inventory of materials should be tracked. Inventory is tracked in real-time so that materials will be ordered and delivered promptly, thereby minimizing the risk of defects.

Importance of Supply Chain Management in Resource Delivery

Delivering timely resources is important in construction projects as any delay in providing material will drastically affect the project timeline and also increase the project cost (Babaeian Jelodar, Hemant Raut and Saghatforoush, 2021). Controlled supply chain management implies that materials and equipment come in at the right time, thus avoiding idle time and maximising the productivity of labour.

In addition, cost control and budget compliance depend on effective supply chain management (Babaeian Jelodar, Hemant Raut and Saghatforoush, 2021). The benefits for construction companies include nonguilty negotiation with suppliers and reducing nonessential costs of emergency procurement or shortage of materials through bulk purchases or long-term contracts. The controller that manages the supply chain process effectively makes sure that the materials are sourced at a relatively low cost and with maintained quality standards (Heaton et al., 2022).

Supply chain management also includes another vital aspect known as quality assurance (Bekrar et al., 2021). Regular work with reliable suppliers and quality checks are the ways project managers can ensure project specifications are met. The strict quality control measure ensures the non use of substandard materials ,whereby one is sure to avoid the weakening of the structural integrity and safety.

One of the essential risk mitigation factors is construction supply chain management (Das et al., 2021). However, a supply chain strategy offered by a diversified supplier can help to reduce the risk of delay in materials by minimizing dependence on a single supplier and thus reducing shortages, price fluctuation or logistical problems (Das et al., 2021). With the potential that such disruptions could affect project teams, project teams implement contingency plans, including alternative suppliers and backup transportation options.

Sustainability is considered in modern construction projects (Stanitsas, Kirytopoulos and Leopoulos, 2021). Sustainability goals are attempted to be compensated with eco friendly sourcing, sustainable suppliers, and being under environmental regulations. Materials selection of low carbon footprints and an efficient way to pass materials through the production process lead to a more sustainable construction process (Stanitsas, Kirytopoulos and Leopoulos, 2021).

Challenges in Resource Planning and Supply Chain Management

The problem may have been planned out carefully, but there may be resource allocation and supply chain coordination challenges. High demand or production delays can leave a project stuck. Material shortages can cause project timelines to extend and progress to halt (Olanrewaju et al., 2021). Logistical inefficiencies, traffic conditions or supply chain issues may cause transportation delays, sometimes slowing down project schedules. Furthermore, price fluctuations in major construction materials, namely steel and cement, will impact cost estimation and, therefore require budget changes.

Project execution can also be affected by labour shortages and if the skilled workers aren’t available at the right time during the project (Pamidimukkala and Kermanshachi, 2021). It is essential to ensure workforce availability using good scheduling and contingency hiring plans to continue making progress. Besides, adverse weather conditions may further complicate resource planning by delaying the transport and construction activities, calling for buffer time in the project schedules (Pamidimukkala and Kermanshachi, 2021).

Theories and practical considerations of resource management

Resource management in the construction industry is effective if the strategic allocation of human, material, and financial resources is made to achieve project efficiency and control, as well as the achievement of a complete project in time. A construction project requires integrating long-term workforce management strategies, resource levelling techniques, and systematic planning and scheduling processes (Leerapan et al., 2021). Furthermore, modern human resource management principles understand employees as vital assets for deciding the success of a project and the survival of a business generally.

Long-Term Strategies for Workforce Management and Development

It is necessary to have long-term strategies for empowering workforce in the construction industry through training, retention and increased productivity (Park, Kim and Nguyen, 2021). Continuous professional development (CPD) is one of the key strategies in ensuring that workers are as competent and flexible as possible in adopting new construction technologies and regulations (Park, Kim and Nguyen, 2021). Reduction of workplace accidents as well as improvement of overall productivity, is possible through training programs, especially in health and safety.

It also plays an important role of ensuring long-term availability of skilled labour employing workforce planning and succession management (Venkat et al., 2023). Companies can use their future workforce requirements based on project demand to deploy apprenticeship programs and collaborate with vocational training institutions to build a stream of qualified employees. These initiatives can help in addressing labour shortages and offer to young professionals structured paths to enter the field of construction (Venkat et al., 2023).

A performance management system based on incentives increases workforce motivation and efficiency. To get commitment and high performance from employees, companies usually put bonuses linked to productivity or other promotion programs, as well as recognition programs and career progression programs (Ali, 2021). This has got a motivated workforce that’s less likely to go leave your company on behalf of competitors as turnover cost.

Workforce diversity and inclusion strategies are implemented because they help to attract and retain a larger pool of talent throughout the construction sites, resulting in creativity and supporting teamwork (Karakhan et al., 2021). EvanSport ensures that all of its staff are operating in a compliant manner with the Equality Act 2010 and, for that reason, looks to create an inclusive working environment where all employees are treated fairly and in a productive way that minimises conflicts and promotes collaboration.

Resource Levelling as a Fast-Tracking Construction Technique

A project management technique for resource levelling occurs when the project schedule is adjusted to prevent overburdening the labour and equipment (Kiungo and Otieno, 2023). Resource levelling is the technique to be used in the construction industry so that resources are properly utilized to keep the workflow smooth without overloading the specific roles of the project.

In the concrete pouring phase, this apartment block project has a practical example of resource levelling (Kiungo and Otieno, 2023). First the construction plan as drawn initially needs all core concrete foundations to be poured in three days. However, due to the lack of availability of concrete mixers and workforce constraints, this is not possible (Weerapura et al., 2023). Concrete pouring is scheduled for five days as opposed to three, and job resources are controlled for this by resource levelling in order to keep resources from being burdened.

The Three Key Steps in Planning and Scheduling: Allocation, Aggregation, and Scheduling

Resource Allocation

The assignment of resources, labour, machinery, and materials to the tasks in the plan is the first step in the planning (Ansari, Kohl and Sihn, 2023). Therefore by allocation, the right quantity of resources is assigned to each phase of the project. The excavation of the phase of an apartment block construction uses an excavator, well-trained operators, and site supervisors.

Resource Aggregation

Aggregation is the combination of the requirements for the resources across different project stages to determine the total requirements of the resources (Akhtar et al., 2021). Project managers can aggregate resources, identify possible shortages or excess of labour and materials, and react to them before scheduling.

Resource Scheduling

Scheduling takes care of the time when the commissioned and aggregated resources are (or will be) used during the lifecycle of a project (Doukari, Seck and Greenwood, 2022). This includes using detailed Gantt charts, the Critical Path Method (CPM) or other project scheduling tools to develop their detailed timelines. Next, we have to consider the potential risks such as weather delays, labour availability and material availability shortage.

Workforce as an Asset in Modern Human Resource Management

In modern human resource management, the workforce is seen as a key asset rather than an expense (Hrušovský et al., 2021). By staffing projects with employees who contribute to project success through expertise, innovation and efficiency in construction operations, comparatively more profits may be earned within the reporting period (Hrušovský et al., 2021). Workforce development is good for the employer since it improves productivity, reduces turnover, and enhances the company’s reputation with the industry.

Knowledge Retention is one of the primary considerations as to why the workforce is deemed an asset (Zayed et al., 2022). The technical expertise of skilled workers and experienced engineers helps make better decisions and solve the construction site's problems. Companies must fill the knowledge gap, replace trained employees, invest in retraining, and recruit staff.

Further, other critical factors are employee engagement and morale (Susanto, 2022). Workers are more committed and motivated when fairly paid, receive training opportunities, and work in a safe environment. Higher engagement levels result in better safety compliance, and increased efficiency levels improve work quality, benefiting the construction company.

Strip Foundation Construction

Process of Constructing a Strip Foundation

Site preparation is the first step in the process, where the site is cleared (vegetation and debris) in order to begin the construction process (Purchase et al., 2021). Then the site is marked out according to its foundation plan so that the trenches are in the proper positions. It is then excavated and trenches are dug to the prescribed depth and width. Levelled and compacted to act as a solid base for the concrete, the trench base is made (Purchase et al., 2021). The reinforcement is then placed over a smooth base of blinding concrete covering up to a layer of the original footing. Steel reinforcements are cast within the trench to strengthen the foundation (Worlanyo and Jiangfeng, 2021). When everything is ready, the concrete is poured into the trenches and allowed to harden. The foundation is built of brickwork or blockwork after curing, and the area around it is backfilled.

Activities, Dependencies, and Timeframes

The table below outlines the different activities involved in constructing the strip foundation, including their dependencies and estimated timeframes:

|

Activity ID |

Activity Name |

Predecessor(s) |

Duration (Days) |

|

A |

Site Clearing and Preparation |

None |

2 |

|

B |

Marking Out Foundation |

A |

1 |

|

C |

Excavation of Trenches |

B |

3 |

|

D |

Compacting and Leveling Base |

C |

1 |

|

E |

Blinding Concrete Placement |

D |

1 |

|

F |

Reinforcement Installation |

E |

2 |

|

G |

Concrete Pouring |

F |

2 |

|

H |

Curing of Concrete |

G |

3 |

|

I |

Blockwork Construction |

H |

3 |

|

J |

Backfilling and Finalization |

I |

2 |

Network Diagram with ES, LS, EF, LF

Interpretation of the Network Diagram

The strip foundation sequencing shows the network diagram of construction activities sequencing, including their dependencies and limitations for the time requirements for completing each phase of the strip foundation (Chen et al., 2022). Through the use of the ES, EF, LS, and LF values, we can discover the amount of time required to complete the project, identify the critical path and check for activities that have float (slack), thus leaving the project work flexible.

Project Duration

The duration from beginning to end for constructing the strip foundation is given by the longest sequence of dependent activities. The total project duration can be calculated based on the calculated values of the network diagram, which amounts to be 20 days. Therefore, if all activities are completed on schedule, the foundation will be ready to go to the next construction phase in 20 days.

Critical Activities and the Critical Path

The sequence of activities that must be completed on time for the project to be on schedule is known as the critical path. Delays in these activities will directly lead to a delay of the overall completion of the strip foundation.

A (Site Clearing and Preparation) → B (Marking Out) → C (Excavation of Trenches) → D (Compacting and Leveling Base) → E (Blinding Concrete Placement) → F (Reinforcement Installation) → G (Concrete Pouring) → H (Curing of Concrete) → I (Blockwork Construction) → J (Backfilling and Finalization).

There are no slack in each of these activities because they don’t have any space to be shifted. Any of them being delayed will delay the entire foundation completion timeline.

Slack Time (Float) Analysis

Float or slack time is when you can delay an activity without delaying the project completion date (Wambura, 2024). If they have slack, then activities can be scheduled with some time flexibility with minor delays that will not significantly change the subsequent activities. Because all significant activities are on the critical path in this project, there is no slack time for rescheduling or delays. This implies that the foundation must be built within the assigned 20 days and that every activity has to start and finish as scheduled. Project managers will have to go to the next phase of making corrective decisions such as resource reallocation, overtime work or activity fast-tracking to maintain the project schedule if unexpected situations, for example, bad weather, equipment failure or material delivery delays, arise unexpectedly (Ronak, 2024).

Project Management Recommendations

- Material Procurement Planning: Order concrete, reinforcement steel, and excavation equipment early enough not to delay.

- Continuous progress on activities like curing and blockwork can be obtained if as many shifts as possible can be assigned.

- Daily tracking and monitoring of progress: Detect and mitigate potential delays to the critical path before they occur.

- Unforeseen Issues: Activities such as excavation and reinforcement installation can be improved by boosting labour and machinery availability.

Conclusion

Completing the strip foundation for the three-bedroom apartment block depends on effective resource management and scheduling. The network diagram analysis shows that the project has a well-defined sequencing of each activity, and each activity relies on the completion of the preceding task at the right time. The total project duration is 20 days, so the construction of the foundation should be monitored closely to prevent any delay that may affect the total project duration.

Essential activities, such as site clearing, excavation, compacting, reinforcement installation, concrete pouring, curing, and blockwork construction, are identified as critical paths and must be adhered to as scheduled. Since all these tasks have zero slack, the project has less flexibility. Interruption of any of these activities' kernel impedes the foundation's completion date, affecting the whole project.

Preventive planning is necessary to mitigate the potential risks of such planning. Controls that will keep the project on track include timely procurement of materials, efficient allocation of labour and equipment, and continual progress monitoring. Furthermore, strategies to tackle unexpected hurdles without missing the project deadline, such as fast-tracking or reallocating resources, would be adopted.

By implementing these structures in planning and scheduling, the construction company's strip foundation project shall be satisfactorily accomplished within the allowable duration of time while maintaining the government's expectation of minimizing cost and efficient appropriation. The successful completion of the project is heavily reliant on efficient management of this phase, which will also set a strong foundation on both literal and figurative terms.

Operations and resource management assignments in construction demand a strong balance of theory, practical application, critical analysis, and structured academic presentation. Students often struggle to integrate workforce planning models, scheduling techniques, legal compliance, and real-world construction scenarios within tight word limits. Professional assignment help can support you in organising complex content, strengthening critical evaluation, and ensuring accurate referencing and alignment with CMA4004 marking criteria, ultimately helping you achieve higher academic outcomes with confidence.

References

Akhtar, N., Ishak, M.I.S., Ahmad, M.I., Umar, K., Md Yusuff, M.S., Anees, M.T., Qadir, A. and Ali Almanasir, Y.K. (2021). Modification of the Water Quality Index (WQI) Process for Simple Calculation Using the Multi-Criteria Decision-Making (MCDM) Method: A Review. Water, [online] 13(7), p.905. doi:https://doi.org/10.3390/w13070905.

Ali, B.J. (2021). An Empirical Study of Employees’ Motivation and Its Influence Job Satisfaction. [online] papers.ssrn.com. Available at: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3822723.

Amer, F. and Golparvar-Fard, M. (2021). Modeling dynamic construction work template from existing scheduling records via sequential machine learning. Advanced Engineering Informatics, 47, p.101198. doi:https://doi.org/10.1016/j.aei.2020.101198.

Ansari, F., Kohl, L. and Sihn, W. (2023). A competence-based planning methodology for optimizing human resource allocation in industrial maintenance. CIRP Annals, [online] 72(1), pp.389–392. doi:https://doi.org/10.1016/j.cirp.2023.04.050.

Anwar, G. and Abdullah, N.N. (2021). The Impact of Human Resource Management Practice on Organizational Performance. [online] SSRN. Available at: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3824689.

Assaad, R. and El-adaway, I.H. (2021). Impact of Dynamic Workforce and Workplace Variables on the Productivity of the Construction Industry: New Gross Construction Productivity Indicator. Journal of Management in Engineering, 37(1), p.04020092. doi:https://doi.org/10.1061/(asce)me.1943-5479.0000862.

Babaeian Jelodar, M., Hemant Raut, P. and Saghatforoush, E. (2021). Contractor-Delay Control in Building Projects: Escalation of Strategy from Primary Proactive to Secondary Reactive. Journal of Legal Affairs and Dispute Resolution in Engineering and Construction, 13(2). doi:https://doi.org/10.1061/(asce)la.1943-4170.0000449.

Bekrar, A., Ait El Cadi, A., Todosijevic, R. and Sarkis, J. (2021). Digitalizing the Closing-of-the-Loop for Supply Chains: A Transportation and Blockchain Perspective. Sustainability, 13(5), p.2895. doi:https://doi.org/10.3390/su13052895.

Chen, K.M., Wong, A.K., Troyanskaya, O.G. and Zhou, J. (2022). A sequence-based global map of regulatory activity for deciphering human genetics. Nature Genetics, [online] 54(7), pp.940–949. doi:https://doi.org/10.1038/s41588-022-01102-2.

Das, D., Datta, A., Kumar, P., Kazancoglu, Y. and Ram, M. (2021). Building supply chain resilience in the era of COVID-19: An AHP-DEMATEL approach. Operations Management Research, 15(13). doi:https://doi.org/10.1007/s12063-021-00200-4.

Doukari, O., Seck, B. and Greenwood, D. (2022). The Creation of Construction Schedules in 4D BIM: A Comparison of Conventional and Automated Approaches. Buildings, [online] 12(8), p.1145. doi:https://doi.org/10.3390/buildings12081145.

Heaton, R., Martin, H., Chadee, A., Milling, A., Dunne, S. and Borthwick, F. (2022). The Construction Materials Conundrum: Practical Solutions to Address Integrated Supply Chain Complexities. Journal of Construction Engineering and Management, 148(8). doi:https://doi.org/10.1061/(asce)co.1943-7862.0002326.

Hrušovský, M., Demir, E., Jammernegg, W. and Van Woensel, T. (2021). Real-time disruption management approach for intermodal freight transportation. Journal of Cleaner Production, 280, p.124826. doi:https://doi.org/10.1016/j.jclepro.2020.124826.

HSE (2015). How many toilets should a workplace have? [online] Hse.gov.uk. Available at: https://www.hse.gov.uk/contact/faqs/toilets.htm.

Jamal, T., Zahid, M., Martins, J.M., Mata, M.N., Rahman, H.U. and Mata, P.N. (2021). Perceived Green Human Resource Management Practices and Corporate Sustainability: Multigroup Analysis and Major Industries Perspectives. Sustainability, [online] 13(6), p.3045. doi:https://doi.org/10.3390/su13063045.

Jaśkowski, P., Biruk, S. and Krzemiński, M. (2021). Proactive scheduling of repetitive construction processes to reduce crews idle times and delays. Archives of Civil Engineering, [online] Vol. 67(nr 4). doi:https://doi.org/10.24425/ace.2021.138500.

Karakhan, A.A., Gambatese, J.A., Simmons, D.R. and Al-Bayati, A.J. (2021). Identifying Pertinent Indicators for Assessing and Fostering Diversity, Equity, and Inclusion of the Construction Workforce. Journal of Management in Engineering, 37(2), p.04020114. doi:https://doi.org/10.1061/(asce)me.1943-5479.0000885.

Khalid, U., Sagoo, A. and Benachir, M. (2021). Safety Management System (SMS) framework development – Mitigating the critical safety factors affecting Health and Safety performance in construction projects. Safety Science, 143(0925-7535), p.105402. doi:https://doi.org/10.1016/j.ssci.2021.105402.

Kiungo, J.W. and Otieno, J.A. (2023). Resource Optimization Techniques and Sustainability of Gated Community Construction Projects in Nairobi County, Kenya. Journal of Human Resource and Sustainability Studies, 11(03), pp.635–649. doi:https://doi.org/10.4236/jhrss.2023.113035.

Leerapan, B., Teekasap, P., Urwannachotima, N., Jaichuen, W., Chiangchaisakulthai, K., Udomaksorn, K., Meeyai, A., Noree, T. and Sawaengdee, K. (2021). System dynamics modelling of health workforce planning to address future challenges of Thailand’s Universal Health Coverage. Human Resources for Health, 19(1). doi:https://doi.org/10.1186/s12960-021-00572-5.

Lin, J., Chiu, I. and Chou, C. (2025). Conquering the ‘Collected Treasures’ of Older Adults With Dementia: A Qualitative Study on Caregiver Strategies and Challenges. Journal of Advanced Nursing. doi:https://doi.org/10.1111/jan.16727.

Marzouk, M. and Sabbah, M. (2021). AHP-TOPSIS social sustainability approach for selecting supplier in construction supply chain. Cleaner Environmental Systems, 2, p.100034. doi:https://doi.org/10.1016/j.cesys.2021.100034.

McEwan, A., Price, L., Suzuki, M., Pascoe, V., Lorenza, L., Bloomfield, C., Power, D. and Stanton, L. (2025). Rural Youth Participation in Youth Justice Research: Towards a Rights-Based Approach. Youth Justice. doi:https://doi.org/10.1177/14732254241310691.

Olanrewaju, A., AbdulAziz, A., Preece, C.N. and Shobowale, K. (2021). Evaluation of measures to prevent the spread of COVID-19 on the construction sites. Cleaner Engineering and Technology, 5(4), p.100277. doi:https://doi.org/10.1016/j.clet.2021.100277.

Pamidimukkala, A. and Kermanshachi, S. (2021). Impact of Covid-19 on field and office workforce in construction industry. Project Leadership and Society, [online] 2(100018), p.100018. doi:https://doi.org/10.1016/j.plas.2021.100018.

Park, C.-J., Kim, S.-Y. and Nguyen, M.V. (2021). Fuzzy TOPSIS Application to Rank Determinants of Employee Retention in Construction Companies: South Korean Case. Sustainability, 13(11), p.5787. doi:https://doi.org/10.3390/su13115787.

Purchase, C.K., Al Zulayq, D.M., O’Brien, B.T., Kowalewski, M.J., Berenjian, A., Tarighaleslami, A.H. and Seifan, M. (2021). Circular Economy of Construction and Demolition Waste: A Literature Review on Lessons, Challenges, and Benefits. Materials, 15(1), p.76. doi:https://doi.org/10.3390/ma15010076.

Rajan, D. (2022). Physical working environment and welfare facilities related factors causing heavy workload: an empirical study among sanitary workers. London Journal of Social Sciences, [online] 2(3), pp.19–52. doi:https://doi.org/10.31039/ljss.2022.3.71.

Rhodes, J. and Bell, S. (2021). ‘“It sounded a lot simpler on the job description”’: A qualitative study exploring the role of social prescribing link workers and their training and support needs (2020). Health & Social Care in the Community, 29(6). doi:https://doi.org/10.1111/hsc.13358.

Ronak, B. (2024). AI-Driven Project Management Revolutionizing Workflow Optimization and Decision-Making - Repository Universitas Muhammadiyah Sidoarjo. Umsida.ac.id. [online] doi:http://eprints.umsida.ac.id/14626/1/ijtsrd71577.pdf.

Saputro, T.E., Figueira, G. and Almada-Lobo, B. (2022). A comprehensive framework and literature review of supplier selection under different purchasing strategies. Computers & Industrial Engineering, 167, p.108010.

Shah, P. and Chandragade, A.A. (2022). Application of project management tool in construction for Planning, Scheduling and Optimization. Materials Today: Proceedings, 77(3). doi:https://doi.org/10.1016/j.matpr.2022.11.446.

Shestakofsky, B. (2024). Cleaning up data work: Negotiating meaning, morality, and inequality in a tech startup. Big Data & Society, 11(3). doi:https://doi.org/10.1177/20539517241285372.

Stanitsas, M., Kirytopoulos, K. and Leopoulos, V. (2021). Integrating Sustainability Indicators into Project management: the Case of Construction Industry. Journal of Cleaner Production, 279(1), p.123774.

Susanto, P.C. (2022). Employee Engagement Strategy: Analysis Of Organizational Commitment, Compensation, Career Development. INTERNATIONAL CONFERENCE OF HUMANITIES AND SOCIAL SCIENCE (ICHSS), [online] pp.96–103. Available at: https://programdoktorpbiuns.org/index.php/proceedings/article/view/134.

Teo, M.E., Sarpin, N., Seow, T.W. and Shafii, H. (2022). The Impact of Human Resources Strategies on Worker’s Performance in Construction Project. Research in Management of Technology and Business, [online] 3(1), pp.509–521. Available at: https://publisher.uthm.edu.my/periodicals/index.php/rmtb/article/view/7153 [Accessed 9 May 2023].

Venkat, M.V.V., Khan, D.S.R.K., Gorkhe, D.M.D., Reddy, M.K.S. and Rao, P.S.S.P. (2023). Fostering Talent Stability: A Study on Evaluating the Influence of Competency Management on Employee Retention in the Automotive Industry. Remittances Review, [online] 8(4). Available at: https://remittancesreview.com/menu-script/index.php/remittances/article/view/882.

Wambura, D.S. (2024). Key Concepts of Participatory Project Planning and Management: An Empirical Review. International Journal of Formal Education, [online] 3(3), pp.147–168. Available at: https://journals.academiczone.net/index.php/ijfe/article/view/2312.

Weerapura, V., Sugathadasa, R., De Silva, M.M., Nielsen, I. and Thibbotuwawa, A. (2023). Feasibility of Digital Twins to Manage the Operational Risks in the Production of a Ready-Mix Concrete Plant. Buildings, 13(2), p.447. doi:https://doi.org/10.3390/buildings13020447.

Worlanyo, A.S. and Jiangfeng, L. (2021). Evaluating the Environmental and Economic Impact of Mining for post-mined Land Restoration and land-use: a Review. Journal of Environmental Management, [online] 279(279), p.111623. doi:https://doi.org/10.1016/j.jenvman.2020.111623.

Zayed, N.M., Edeh, F.O., Islam, K.M.A., Nitsenko, V., Dubovyk, T. and Doroshuk, H. (2022). An Investigation into the Effect of Knowledge Management on Employee Retention in the Telecom Sector. Administrative Sciences, 12(4), p.138. doi:https://doi.org/10.3390/admsci12040138.