Introduction

Power electronics converters are really used in the pattern and executing to expeditiously switch exciting vigor to desired levels. This account focuses on the growing of an all encompassing transcription including a rectifier, buck converter, and boost converter to attain lasting DC outputs to single applications. The transcription commences with an AC source, converted to pulsating DC as well as using a rectifier and filter. The buck convector lowers the possible to a low DC even which is controlled, whereas the boost convector boosts this to an even higher,' lasting DC possible if the load needs it. Each stage is design, alive parameters, and executing was discussed in detail as well as with emphasis on efficiency, rifle reduction, and skill of desired yield specifications in this report. This paper pointed out the need to integrate converters in a succession to attain optimum power principle in modern day lepton applications.

At Native Assignment Help, we provide expert Assignment Help in engineering and electronics subjects. Our professional writers simplify complex concepts like rectifiers, buck converters, and boost converters, ensuring clarity, accuracy, and top-quality academic performance for students in the UK.

Procedure

Rectification Stage

The ferment started by designing a rectifier for the given AC input possible to pulsating DC. It was designed as a full wave rectifier to have a good efficiency ratio and a sander yield of DC. The enlistment used diodes in bridgework configuration, so that both halves of the AC waveform were utilized (Nayak et al., 2021). By adding a condenser after the rectifier as well as the ripples were minimized, and comparatively lasting DC possible was provided for serial conversion.

_68d50af46cb67.jpg)

Figure 1: Activity 1 (Rectifire Design)

Values

Input AC Voltage (RMS):

Vin = 230 V

Peak Voltage Vpeak= 325.3V

Ripple Voltage for Capacitor

Ripple voltage (ΔV)= 32.53V

Required Capacitance

C=6150μF

Buck Converter Design

A buck convector was used to step down the rectified DC possible after chastisement to a lasting 30V output. A buck converter includes an inductor, a diode, a capacitor, and a switching MOSFET controlled using a Pulse Width Modulation signal. The PWM duty cycle was computed based on the input and desired yield voltage. The values of the inductors and capacitors were selected to minimize the riffle and maximized the efficiency of vigor transfer. For the prototype, the load opponent was shown and the enlistment simulated such that yield constancy was maintained.

_68d50b144b202.jpg)

Figure 2: Activity 2 (Buck Converter Design)

Values

Buck Converter Stage

Input Voltage (from Rectifier): Vin=325.3 V

Output Voltage: Vout=30 V

Duty Cycle: D≈9.23%

Inductor Value

L=1.818mH

Capacitor Value

ΔVout = 3V

C = 250μF

Boost Converter Design

A boost converter followed the buck converter,' and was used to promote the 30 DC to a high yield level of 500V DC. This was composed of an inductor, diode, capacitor,' and an unconventional switching MOSFET. The PWM subscribe was set up with a high duty cycle to attain the possible boost required (Zhang et al., 2020). It was arranged with the input possible in series with the inductance to store energy, and a condenser smoothed the boost possible before sending it to the load. The obtained example results were analyzed for possible boost efficiency and yield stability.

_68d50b345fc79.jpg)

Figure 3: Activity 3 (Boost Converter Design)

Values

Boost Converter Stage

Input Voltage (from Buck Converter):

Vin=30 V

Output Voltage:

Vout=500 V

Duty Cycle:

D≈94%

L=1.88mH

Capacitor Value:

C= 15μF

Integration of all Systems

The output of the boost converter was connected to the input of the buck converter to assemble a step-down and step-up voltage regulation system. Stages were made sure to be grounded properly and current flows continuously in the system (Jain et al., 2022). Simulations were carried out on the combined system to check if overall design was meeting the goal of achieving minimal ripples and efficient energy conversion up to 500V output.

_68d50b5843684.jpg)

Figure 4: Activity 4 (Connection between all)

Values

Load Resistance: R=3 Ω

Load Inductance: L=50 mHL

Pulse Generator Settings

Switching Frequency: fs=50 kHz

Period: T= 20μs

Duty Cycle for Buck Converter: Dbuck=9.23%

Pulse Width ≈1.846μs

Duty Cycle for Boost Converter: Dboost=94%

Pulse Width ≈18.8μs

Performance Analysis

In addition, the performance of the overall system was monitored by observing the output waveforms for the voltage and current (Singh et al., 2023). The ripple voltage was measured to ensure compliance with the specifications outlined in the design. Component values and PWM duty cycle were adjusted as necessary to optimize the system's performance. The results showed successful voltage regulation and efficient energy transfer across all stages.

Findings

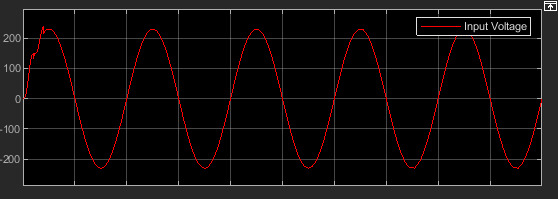

Input Voltage Analysis

The input voltage of the rectifier, as illustrated in Figure 5, is a purely sinusoidal waveform peaking at about 230 V. This waveform corresponds to the AC supply given to the system. As the sinusoidal waveform indicates, the unfiltered AC is being input to the rectifier to ensure that the designed circuit is behaving as it should at the first level of execution.

Figure 5: Rectifier Input Voltage

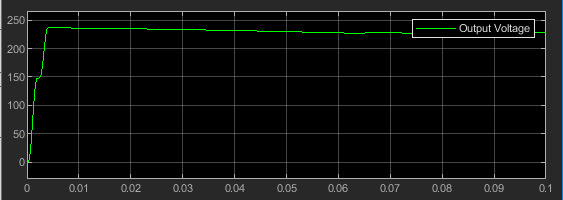

Rectifier Output Voltage

Figure 6 shows the voltage at the output of the rectifier, which is DC with a peak voltage which stabilizes around 250 V. This explains that the rectifier has successfully converted the AC source into DC (Dimitrov et al., 2020). Stability of the waveform proves that the ripple in the output of the rectifier is minimal which further validates that the components used as filters are effective. The rectified voltage is a stable DC source to the following buck converter.

Figure 6: Rectifier OutPut Voltage

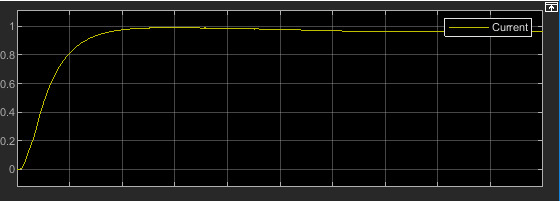

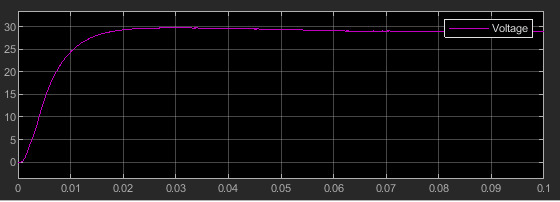

Buck Converter Output

The output from the buck converter in terms of the current is shown in Figure 7 and the voltage in Figure 8. As can be seen, the current output of the buck converter keeps increasing gradually while stabilizing at about 1 A. The voltage output also stabilized at around 30 V, meaning that the buck converter had successfully stepped down the applied voltage (Ali et al., 2023). The fact that minimal voltage ripple, if at all, is present justifies the buck converter's design specifications for a smooth output. These outputs confirm the efficient operation of the buck converter stage in voltage reduction and at the same time maintaining load compatibility.

Figure 7: DC-DC Buck Converter Current Output

Figure 8: DC-DC Buck Converter Voltage Output

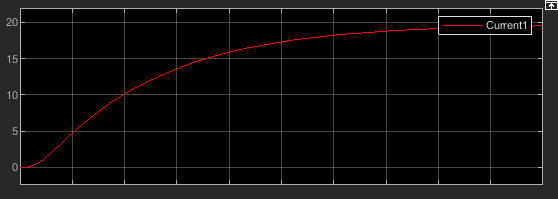

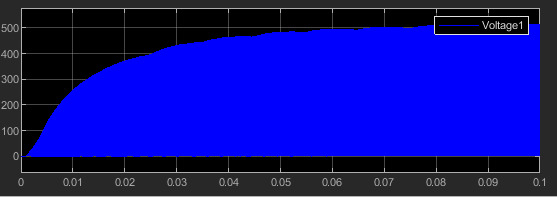

Boost Converter Output

The current and voltage of the boost converter are shown in Figures 9 and 10, respectively. The current output is slowly ramping up but then remains stable at about 20 A, whereas the voltage output reaches the desired 500 V. The progressive rise of the waveform indicates the time constant of the inductance and capacitance of the boost converter (Rajalakshmi and Latha, 2020). Therefore, the output voltage shows low ripple, and the design objective of a stable output of 500 V DC was achieved. This confirms that the output from the boost converter is perfectly stepped up.

Figure 9: DC-DC Boost Converter Current Output

Figure 10: DC-DC Boost Converter Voltage Output

Voltage and Current Stability

Findings of the result indicate stable output values achieved by each step during the process of power conversion. Rectification provides a stable DC output, while the buck converter reduces the voltage down to an intermediate level (Shukla et al., 2023). On the other hand, the boost converter optimally steps up the voltage to 500 V. Current levels are within favorable ranges for supporting load requirements and system reliability.

Ripple Analysis

Ripple voltage was observed throughout all the stages of the circuit. There are minor fluctuations at the boost converter stage, but ripple remains in acceptable limits, and the system works efficiently. Minimizing ripple in the operation and maintaining stable output voltage and current becomes imperative with the help of a capacitor and the inductor used in the filtering parts.

Application of Embedded Systems in Industrial Electronics

Embedded systems are special purpose computing systems intended for working with definite goals within the larger system. It integrates hardware and software components to achieve functionality, efficiency, and control. Basic parts include a microcontroller or a microprocessor, input sensors, output devices, communication interfaces, and power management units (Safayatullah et al., 2022). These components interact with each other in order to successfully perform real-time operations. For example, in a power converter, a microcontroller can be a control unit to decide the level of voltage and operational parameters according to the sensor inputs.

There are three types of embedded systems functional requirements: real-time systems that perform tasks within a strict timeframe, such as an industrial controller; stand-alone systems, independent without specific external input, such as a calculator; and networked systems that are connected to other systems to exchange data, like smart grids.

Embedded systems in a power converter ensure accurate control because they monitor voltage, current, and switching operation in real time (Acharige et al., 2023). It facilitates the implementation of the control unit by executing algorithms for pulse width modulation (PWM), minimizing ripple, and maintaining stability. Incorporating sensors and feedback loops allows the system to make dynamic adjustments in outputs based on input conditions, thus improving efficiency and reliability in industrial applications.

Recommendations

- Enhancing Circuit Design

The enlistment pattern should be optimized by having the right pick and conform sizing of inductors, capacitors, and resistors. In that case,' conform sizing of the components may have reduced the possible ripples significantly. Efficiency and constancy can be exceedingly improved. Also, the arrangement of the components should be standardized to declaration closings and magnetism interference.

- Advanced Control Strategies

The transcription may hike advanced finished internalization of sophisticated check techniques, such as PID check or fuzzy logic, for the advance of its execution (Rajendran et al., 2020). Such methods can hold energizing changes to the way power converters go in control, which guarantees correct principle and constancy under varied loads.

- Improved Pulse Generation

Pulse generators must be optimized with correct duty cycles, frequency, and phase delays for a lasting and continuous output. Optimising the PWM signals can well declare overshooting and ripples in the yield voltage, thus ensuring intact appendage of the DC DC converters.

- Incorporating Feedback Loops

The comprehension of a closed loop feedback transcription would have importantly enhanced the type of the yield (Kadirvel et al., 2023). A true period monitoring of the possible and modern day would have resulted in an energizing fitting of the parameters for the converter, thus maintaining continuous DC and good tracking of load variations.

- Safety and Protection Features

Implementation of safety mechanisms like overcurrent protection, thermal management, and clamping voltage is very important to protect the circuit components from damage. Protective features ensure system reliability and longevity against unexpected failure.

- Future Innovations

Further research work is suggested with advanced modern technologies of DSP's or Embedded Controllers to make automation and control systems more effective, improving the efficiency, and still easily integrating more complex power systems in industrial applications.

Followed by such recommendations, the reliability, efficiency, and overall performance of the system can be substantially improved.

Conclusion

The buck-boost converter system's design and implementation demonstrated effective electrical power conversion, optimized voltage regulation. The integration of rectifiers, DC-DC converters, and control strategies all helped the system produce a steady DC output voltage in various industrial applications. Key components such as inductors, capacitors, and pulse generators played crucial roles in maintaining the stability of the system by reducing voltage ripples.

The results clearly emphasized the grandness of meet sizing of components, feedback loops, and sophisticated check mechanisms in improving the systems' efficiency and reliability. It also addressed the challenges of riffle reduction and pair state stabilization finished single pattern changes and parameter optimizations.

However, it emphasizes the effectiveness of advanced embedded systems and check techniques in power electronics. Future improvements acknowledge the consolidation of advanced controllers and defensive mechanisms, hike enhancing transcription performance, thus making it more flexible to single highly developed demands.

Reference List

Journals

Acharige, S.S., Haque, M.E., Arif, M.T., Hosseinzadeh, N., Hasan, K.N. and Oo, A.M.T., 2023. Review of electric vehicle charging technologies, standards, architectures, and converter configurations. IEEE Access, 11, pp.41218-41255.

Ali, A., Mousa, H.H., Shaaban, M.F., Azzouz, M.A. and Awad, A.S., 2023. A comprehensive review on charging topologies and power electronic converter solutions for electric vehicles. Journal of Modern Power Systems and Clean Energy.

Dimitrov, B., Hayatleh, K., Barker, S., Collier, G., Sharkh, S. and Cruden, A., 2020. A buck-boost transformerless DC–DC converter based on IGBT modules for fast charge of electric vehicles. Electronics, 9(3), p.397.

Jain, A., Gupta, K.K., Jain, S.K., Bhatnagar, P. and Vahedi, H., 2022. A V2G Enabled Bidirectional Single/Three-Phase EV Charging Interface Using Modular Multilevel Buck PFC Rectifier. Electronics, 11(12), p.1891.

Kadirvel, K., Kannadasan, R., Alsharif, M.H. and Geem, Z.W., 2023. Design and Modeling of Modified Interleaved Phase-Shifted Semi-Bridgeless Boost Converter for EV Battery Charging Applications. Sustainability, 15(3), p.2712.

Nayak, P.S.R., Kamalapathi, K., Laxman, N. and Tyagi, V.K., 2021, January. Design and simulation of BUCK-BOOST type dual input DC-DC converter for battery charging application in electric vehicle. In 2021 International Conference on Sustainable Energy and Future Electric Transportation (SEFET) (pp. 1-6). IEEE.

Rajalakshmi, C. and Latha, R., 2020. Design of Power Factor Correction Controller using Buck-Boost Converter in Wireless Charging System for Electric Vehicle.

Rajendran, G., Vaithilingam, C.A., Naidu, K. and Oruganti, K.S.P., 2020. Energy-efficient converters for electric vehicle charging stations. SN Applied Sciences, 2, pp.1-15.

Safayatullah, M., Elrais, M.T., Ghosh, S., Rezaii, R. and Batarseh, I., 2022. A comprehensive review of power converter topologies and control methods for electric vehicle fast charging applications. IEEE Access, 10, pp.40753-40793.

Shukla, T., Prasad Patidar, N. and Adhikari, A., 2023. A power factor profile‐improved EV charging system using bridgeless Buckboost‐Cuk converter. International Transactions on Electrical Energy Systems, 2023(1), p.9713102.

Singh, A., Gupta, J. and Singh, B., 2023. Design and control of two stage battery charger for low voltage electric vehicles using high gain buck-boost PFC AC-DC converter. IEEE Transactions on Industry Applications, 59(5), pp.6125-6135.

Zhang, D., Guacci, M., Haider, M., Bortis, D., Kolar, J.W. and Everts, J., 2020, October. Three-phase bidirectional buck-boost current DC-link EV battery charger featuring a wide output voltage range of 200 to 1000V. In 2020 IEEE Energy Conversion Congress and Exposition (ECCE) (pp. 4555-4562). IEEE.