Design Options

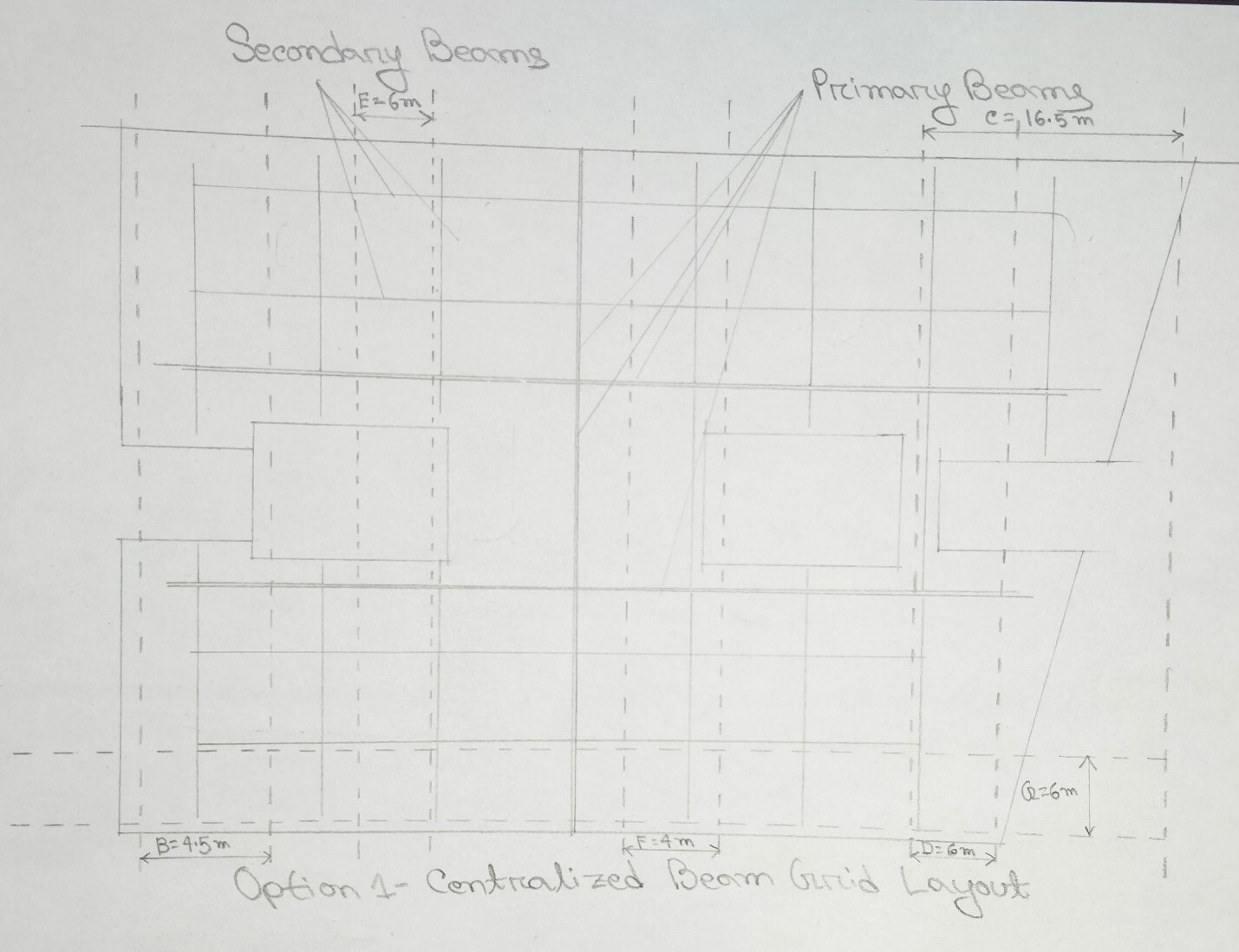

Option 1: Centralised Beam Grid Layout

It has a balanced design and has an arrangement of beams that are in the form of a circle with a central station.

Beams: For the primary beams it is preferred to draw 4 beams running down from the centre of the floorplate with say about 8-10 metres in-between each beam (Li et al. 2022). These beams should be depicted with wider line thickness than the thin, overlapping diagonals.

Secondary Beams: Join secondary beams starting from the primary beams up to the edge to make a symmetrical grid. These beams should be crossing the primary beams at right angles and could be arranged every 5-6 metre interval. These beams should be represented with thinner lines to show that they possess less amount of strength.

Figure 1: Design Option 1

Tertiary Beams: The tertiary beams should be drawn passing through the spaces of secondary beams. These will also be thinner lines.

There should be straight line at the edge of the slab and should run through the perimeter of the slab.

Core and Slabs: This design indicates any slab openings that are situated close to the central core for services (Chaudhary et al. 2021). These should be positioned close to most intersections of beams – for vertical ducts or risers.

Web openings: Classify and mark web openings in the primary beams where web service ducts can be facilitated in the close vicinity of the centre of the floorplate.

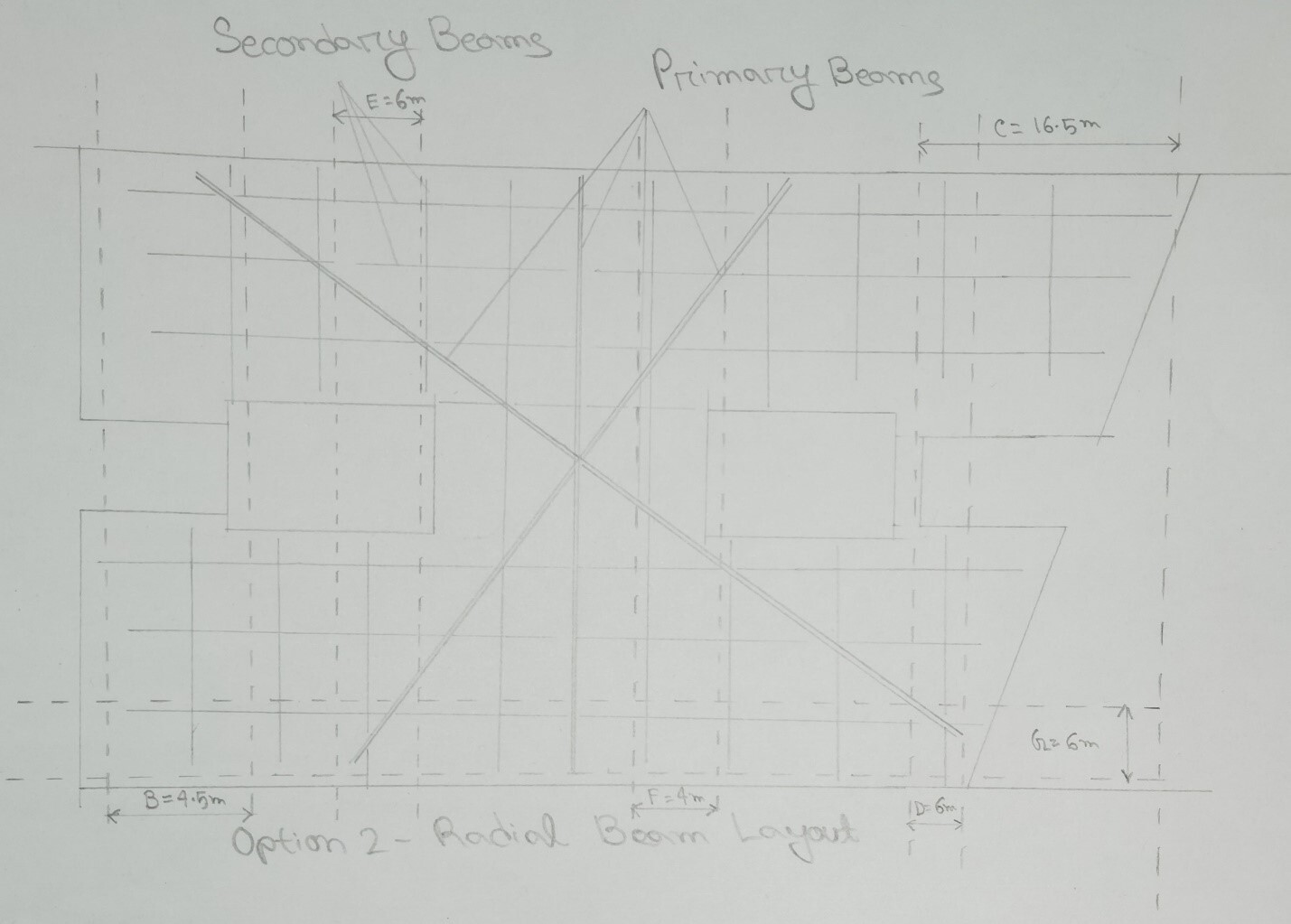

Option 2: Radial Beam Layout

This layout has radiating beams with columns on the edges that extend towards the core of the floorplate.

First, horizontal beams should be drawn from the primary core. There must be 6-8 initial beams that should be spread in all directions or radials, each of them being about 8-10 metres apart one from the other. Represent primary beams with thicker lines.

Figure 2: Design Option 2

Secondary beams: draw secondary beams where they are oriented radially about the primary beams they are joined to in a fashion resemble the spokes in the wheel. These beams will cross the primary beams and as a result they will be referred to as cross beams (Zhao et al. 2023). Represent these with thinner lines.

Tertiary Beams: Draw tertiary beams at right angles to the secondary beams. These should also be thinner lines.

Slab Edges: The positions of the slab edges should be drawn according to the radial form. This has to conform to the radial design you have chosen for the structure, in which you can also make the slab edge slightly curved.

They can also open some slab openings about the outer perimeter of the building to incorporate external elevator shafts and service duct works.

Secondary Beams: If there are web openings in the secondary beams near the core of the building then provide space for passage of the service routes either in the form of HVAC ducts or pipes.

Option 3: Radial Beam Layout

Wired beams proposed here create a rectangular pattern, which is typical for many skeletons in the construction industry.

Primary Beams: Draw primary beams running along the long direction of the building at intervals of 10-12 metres. These beams shall be located in perpendicular manner in relation to the shorter side of the rectangle, which makes up for the floor plate (Reddy et al. 2023). Draw these beams with thick lines or make thicker in comparison to the rest of the beams in the diagram.

Secondary Beams: Place secondary beams along the shorter span in the area of the building , this has a spacing of 5-6m. These two will be placed such that they will lie along the width of the concrete… These will lie perpendicular to the main beams. Draw such beams thinner than the former ones.

Tip: Additional Beams – Minor beams need to be drawn between the secondary ones in the places where the slab is believed to demand more support. These should be thinner lines.

Transfer Beams: It should also show transfer beams that will run parallel to the longer direction of the building (Zhang et al. 2022). These will be larger and may necessitate stronger beams, especially where greatly distributed loads are to bear upon them such as region of service shafts. These beams should be drawn as thicker lines and connected to the column flange webs as also shown below:

Slab Edges: The edges of the slab should be drawn straight in the shape of rectangles.

Continuations: It is also important to place larger slab openings at the core zones around the vertical risers or service shafts.

Web openings: Mark some web openings in the transfer beams to accommodate large building services like ducts for ventilation, electrical conduits etc.

Selection of slab & metal decking to reduce material use

|

Option |

Slab Thickness |

Metal Decking Type |

Decking Thickness |

Advantages |

|

Centralized Beam Grid Layout |

200 mm |

Composite Metal Decking (60 mm deep profile) |

60 mm |

Good in distribution of load, less material because of the interconnection of the composite system, suitable for grid pattern. |

|

Radial Beam Layout |

150 mm |

Lightweight Composite Metal Decking (45 mm deep profile) |

45 mm |

These include use of lightweight slab and decking that is required for material efficiency and ability to support the radial loads in addition to being suitable for complex geometries. |

|

Rectangular Grid with Transfer Beams Layout |

175 mm |

Trough Metal Decking (50 mm deep profile) |

50 mm |

Precast slab and trough decking offer economic and quick construction procedure with less quantity of materials consumed and adequate strength for the grid as well as the transfer beams. |

Identification of Web opening requirement

Option 1

Here, beams form geometrical shapes such as squares and rectangles with the help of columns and cover the entire area in a manner which shows proper geometrical symmetry.

Primary Beams:

These beams are meant to take most of the loads and that is why web openings may be necessary near the building core if the space is to be provided for electrical risers, water pipes or ducting systems which are normally arranged along the core area in most buildings (Tao et al. 2021). These web openings should be placed at the areas where primary beams are connected, most probably where service ducts will be placed.

Secondary Beams:

Stairs web openings may be required at the locations where the secondary beams cross the primary beams particularly if they support larger duct or risers. Sometimes the ducts may run alongside the secondary beam axis, and therefore, apertures may be made at intersecting beams.

Tertiary Beams:

Fewer web openings would be needed at this place because tertiary beams have less loads and generally serve small part of service routes. However, web openings could be open when ducts or pipes require to be placed parallel to these beams though they are perhaps not so common.

Key Areas for Web Openings:

Primary beams at the center of the floorplate near the core.

Secondary beams at intersections with the primary beams, especially near vertical riser shafts or service routes.

Option 2

This layout involves construction of beams that are originated within a central point or circle. Some of the characteristic features of this layout are that the web openings will be located around the two central core and alongside the two radial beams.

Primary Beams:

As these beams protrude from the core, they are very susceptible to requiring web openings for the primary building services such as electrical wiring, pipes, and ductworks which are usually located within the core of the building (Romero et al. 2024). Secondary beams will have their webs more or less opened along the centreline of the beams and at the junction with the core.

Secondary Beams:

Another feature that is similar to the primary beams is that the secondary beams also spread outwards and may require web openings, where they connect with the primary beams or near service core zones. These beams can further accommodate some ducts or pipes of a comparatively smaller size.

Tertiary Beams:

Tertiary beams as you already mentioned themselves do not necessarily require web openings but if the service pathways are to be located in the close vicinity of these beams, web openings may be required for smaller infrastructure elements such as the HVAC system or small piping.

Key Areas for Web Openings:

Primary beams within core areas that contain the services such as HVAC, plumbing, and electrical among others are expected to go through it.

Secondary beams below areas that touch main beams which are potential areas for linking service routes to the core.

Option 3

This layout comprises rectangular grids having transfer beams where long spans are distinctive.

Primary Beams:

Like in Option 1, in this layout primary beams are also supposed to support great loads and thus at their intersections with the service core web openings should be provided where main service ducts such as HVAC or electrical risers are located (Song et al. 2022).

Where the services require running along the long spinal line of the building like electrical and plumbing risers, then web openings ought to be located either in the central portion or about the service shafts.

Secondary Beams:

In this case, Web openings will probably be needed at the junctions between beams and primary beams especially in cases where the services are perpendicular to these beams. These secondary beams are said to accommodate ducts or pipes that interconnect with other large central service areas.

Transfer Beams:

It is important to note that transfer beams are congregated as they support more loads as compared to the regular beams and also cover more spaces. When these beams are required to span them (for various spaces), it might be necessary to achieve large web openings to accommodate ducts and pipes or other such necessities (Liu et al. 2022). These would normally be positioned at approximately mid-length of the transfer beams, with special bearing to portions of the structure most frequently used.

Key Areas for Web Openings:

Primary beams near the central service core or service shafts.

Secondary beams at intersections with primary beams near service connections.

Transfer beams are used where large services ducts, or systems are required to run, and may be located at mid span.

Advantages & Disadvantages of Different Layout System

|

Layout |

Advantages |

Disadvantages |

|

Centralized Beam Grid Layout |

Efficient load distribution. Clear service pathways. It is also important that this was done in that the construction of the symmetrical grid one has provided is very simple. Flexibility for services. |

Higher material usage because there are big primary beams.Small columns can be used due to less material. Services may interfere with beams to some extent. Possibility of more number of web openings in primary as well as secondary beams for the given load. |

|

Radial Beam Layout |

Centralized service core. Unique aesthetic. Reduced beam lengths and material usage in some cases. |

Complex structural analysis and design. More web openings required. Wasted space in non-circular layouts. |

|

Rectangular Grid with Transfer Beams Layout |

Maximizes usable floor area. Safer and easier to build though is what I was able to establish about the two structures when comparing them. Flexible for future modifications. |

Complexity due to transfer beams. More webs openings particularly in the transfer beams. In the case of the transfer spans, there are larger beam sizes and more use of materials. |

Selection of Layout and its justification

For those reasons, Out of all four plans I recommended ‘’Rectangular Grid with Transfer Beams Layout’’ for construction due to its simplicity and flexibility and the cost factor. This is because the rectangular grid structure is well known and preferable, especially in the design and development stages (Legese et al. 2024). It also minimises the various elements used by properly arranging beams and ensuring that hardly any space is left unused; and is less costly compared to the different options such as the radial one.

This layout is economical, as it is employing the use of locally accessible and industryized products and ways of construction, hence the reduced cost of production. The predictable grid work has the advantage that can be quickly developed, fewer mistakes are likely to occur, and services can easily be integrated since beams are repetitive which makes it easy to run services such as heating and cooling or plumbing. As stated Above, web openings for services are easy to plan at beam intersections minimising interferences.

The rectangular grid layout also has an advantage when there are changes that might be made as time goes by. As for the operational characteristics, the layout or service routes can easily be changed without much effort while in the case of radial layouts, one experiences a lot of resistance because of the complexity of the design (Almutairi et al. 2023). This aspect makes it suitable for purposes of different kinds of buildings such as offices and commercial buildings making it flexible to cater for changes in the activities that might be conducted within the buildings.

This is so because, unlike in the Option 1; Centralised Beam Grid, P’s utilisation of more material in its central core and with potential complication in the organisation of services. Option 2 (Radial Beam) though provides a better appearance to beams and web openings add complexity and limitations to selection of span and shape of beams specifically while changing layout in future (Huang et al. 2022).

Therefore, the rectangular grid with transfer beams layout is the best option due to the ease of construction, use of materials, integration of the services, and ability to accommodate changes in the future that is in consideration with the typical building projects.

Calculations

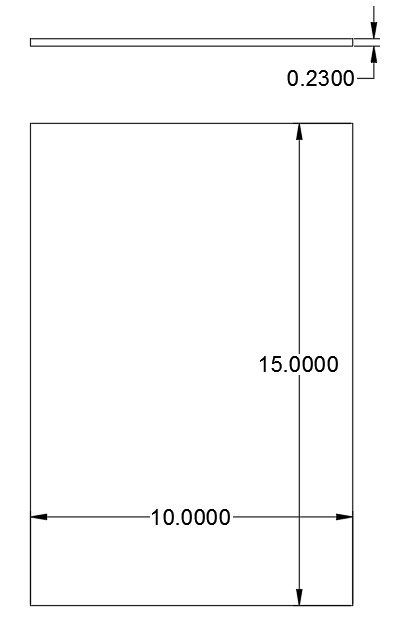

Slab Calculation

Floor dimensions: 10 m x 15 m

Dead load of slab: 3.6 kN/m²

Live load: 7.2 kN/m²

Wind load: 0.9 kN/m²

Concrete grade: C30/37

Concrete density = 24 kN/m³

Grade of steel for reinforcement: S275 (with yield strength of 275 MPa)

Figure 3: Slab Section

Total load per unit area will be:

Considering “simply supported” beam

Considering a depth with the following formula

h = thickness of slab (m)

l = slab span (m)

Bending Moment,

M = moment (kNm)

w = load intensity (kN/m2)

l = span

Totak load,

Moment of Inertia,

b = slab width (taking 1m width)

h = slab depth (m)

Using the following relation,

fcd = concrete compressive strength

y = neutral axis distance (h/2)

Considering the above relations the depth of the slab should be between 0.12 to 0.15 m. However, considering the large span, the thickness should be in the range 0.2 to 0.25 m. Providing a slab depth of 0.23 m

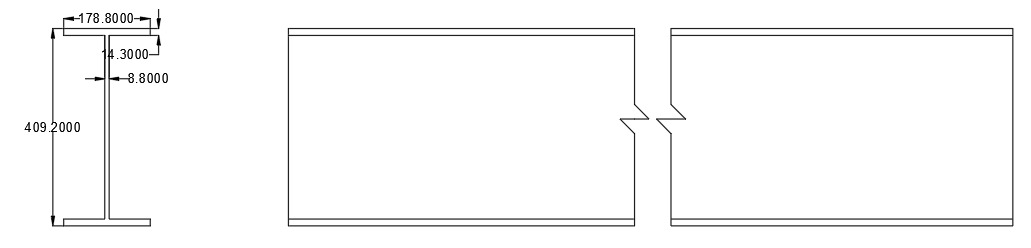

Beam Calculation

Beam Span (l): 10 m

Total Load on Slab: 10.8 kN/m².

Beam Spacing: 9 m

Material: Steel (Grade S275).

Design Strength of Steel (fy): 275 MPa.

Floor Slab Dimensions: 10 m x 15 m.

Beam load (wbeam) = load intensity x beam spacing

wbeam = 10.8 x 9 = 97.2 kN/m

Maximum moment on the beam,

Mmax = wbeam l2/8

Mmax = 97.2 x 102/8

Mmax =1215 kNm

The section modulus is determined from the below relation.

Mmax = fy x S

Here,

fy = yield strength of steel

S = section modulus

Mmax = fy x S

1215 x 106 = 275 x S

S = 1215 x 106/275

S = 4.42 x 106 mm3

Considering the steel section UB 406x178x67

Shear force,

V = wbeam l/2

V = 97.2 x 10/2

V = 486 kN

Shear resistance,

Vrd = α fy Av d

Here,

α = factor considering beam type

Av = web area

d = beam depth

Vrd = 0.6 x 275 x 9600 x 406

Vrd = 643.49 kN > V (hence ok)

Figure 4: Beam Section

Conclusion

In conclusion, the comparative assessment of the three beam layout systems demonstrates that each configuration has specific structural, service integration, and construction implications. The rectangular grid with transfer beams layout proves to be the most efficient and practical solution due to its cost-effectiveness, ease of construction, flexibility for future modifications, and effective accommodation of services. Moreover, the slab and beam calculations confirm that the selected system satisfies strength and serviceability requirements under applied loads, making it suitable for typical commercial and office buildings.

Native Assignment Help provides professional Assignment Help for engineering, construction, and structural design subjects tailored to UK academic standards. Our experts deliver well-structured, calculation-accurate, and plagiarism-free solutions that help students achieve higher grades with confidence. Whether it’s structural design, slab calculations, or technical reports, Native Assignment Help ensures clarity, accuracy, and timely delivery.

Reference List

Journals

Li, Y., Lai, Y., Lu, G., Yan, F., Wei, P. and Xie, Y.M., 2022. Innovative design of long-span steel–concrete composite bridge using multi-material topology optimization. Engineering Structures, 269, p.114838.

Chaudhary, M.K. and Khan, A., 2021. Analysis of a High-Rise Building Frame Considering Wind Pressure Considering Steel RCC composite structure using ETABS. International Journal of Scientific Research in Civil Engineering, 5(6), pp.42-47.

Zhao, J.Z., Tao, M.X., Zhuang, L.D. and Yang, K.Y., 2023, March. Experimental and analytical study on the mechanical properties of U-shaped steel-encased composite beams. In Structures (Vol. 49, pp. 593-604). Elsevier.

Reddy, D.R.S., Yadav, A.C.K. and Srinivas, K., 2023. Comparative analytical study of seismic response and cost of multi-storey (G+ 12) RCC, steel & steel-concrete composite building.

Zhang, Z., Zhang, S.N., Deng, E.F., Yu, C.Y., Tang, Y., Wang, Y. and Sun, D.S., 2022. Shear behavior and design of an innovative embedded connector with flange for steel–concrete composite girder. Archives of Civil and Mechanical Engineering, 22(4), p.195.

Tao, M.X., Li, Z.A., Zhou, Q.L. and Xu, L.Y., 2021. Analysis of equivalent flexural stiffness of steel–concrete composite beams in frame structures. Applied Sciences, 11(21), p.10305.

Romero, A. and Odenbreit, C., 2024. Experimental investigation on novel shear connections for demountable steel-timber composite (STC) beams and flooring systems.(LAJ24. B). Engineering Structures, 304.

Song, Y., Uy, B., Li, D. and Wang, J., 2022. Ultimate behaviour and rotation capacity of stainless steel end-plate connections. Steel and Composite Structures, 42(4), pp.569-590.

Liu, X., Zhang, N., Sun, Q., Wang, K. and Wu, Z., 2022. Parametric Analysis of Structural Noise of Steel‐Concrete Composite Slab Beams. Shock and Vibration, 2022(1), p.3176793.

Legese, A.M., Różański, A. and Sobótka, M., 2024. Effect of shell spacing on mechanical behavior of multi-span soil-steel composite structure. Heliyon, 10(1).

Almutairi, F.F., Tsavdaridis, K.D., Alonso-Rodriguez, A. and Hajirasouliha, I., 2023. Experimental Investigation on Demountable Steel-Concrete Composite Reduced Web Section (RWS) Connections Under Cyclic Loads.

Huang, P., Li, X., Mei, K. and Zhao, Y., 2022. Fatigue tests of composite decks with MCL connectors. Adv. Steel Constr, 18(4), pp.793-803.