Long-Term Performance Of Asphalt Mixture During Freeze-Thaw Cycle By Using Fem

2. Literature Review

2.1 Importance of Road Maintenance and Freeze-Thaw Cycles

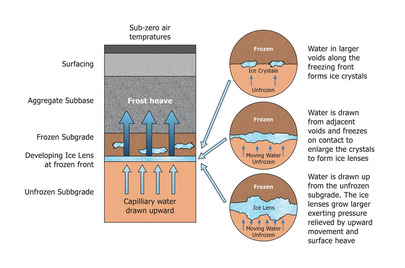

The performance of transportation systems alongside economic development and public protection needs basic road infrastructure. Cold weather cycles create severe damage to asphalt pavements by accelerating their breakdown while driving up maintenance expenses. The asphalt surface accepts water until temperatures drop which causes the water to freeze and expand while creating internal stress (Gao et al. 2023). When water contracts upon thawing it weakens the material structure before microcracks begin to grow and result in damage over time. Repeated freeze-thaw cycles cause surface distress as well as fatigue cracking and potholes while also functioning as the direct cause that makes pavement brittle and prone to breaking from the application of stress.

Figure 2.1: Effect of subgrade soil on Freeze-Thaw Weathering

(Source: Zhang et al. 2024)

Road performance experiences damage when maintenance is delayed and because of this repair expenses increase and road safety faces hazards. The application of a durable asphalt mixture combined with preventive treatments delivers successful outcomes to lengthen pavement existence (Guo et al. 2022). Long-lasting low-cost road infrastructure and transportation through roads in regions with winter temperatures rely on understanding how freeze-thaw cycles affect asphalt performance.

2.2 Effects of Freeze-Thaw Cycles on Asphalt Mixtures

The asphalt mixture is vulnerable to internal stress, microcrack formation, and deterioration because of freeze‐thaw cycles. Water infiltrating into the asphalt and then freezing will expand and place the surrounding structure under pressure. In this expansion, the internal bonds are weakened and microcracks propagate gradually with the repeated cycle (Haghighatpour and Aliha, 2022). During the thawing phase, the material contracts, and the cracks and permeability are further worsened.

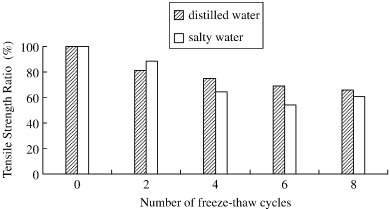

Figure 4.2: Impact of salt and freeze-thaw cycles on performance of asphalt mixtures

(Source: Zhang et al. 2024)

Continuous freeze and thaw will decrease the asphalt's mechanical strength, stiffness, and fatigue resistance over time. But because of the increased permeability, moisture infiltration accelerates, further degrading and loss of structural integrity. Considering all the effects mentioned above, all contribute to premature pavement failure in terms of surface cracks, potholes, and load-bearing capacity. Such problems must be mitigated with improvements in asphalt mix design, moisture resistance, as well as maintenance strategies (Han et al. 2023). The understanding of the long-term effect of freeze-thrust cycles is therefore essential in designing more durable pavements, especially in regions where the temperature extremes are very strong.

2.3 Research Gaps and the Need for Advanced Modeling

Most of the studies on freeze-thaw effects of asphalt mixtures are of empirical and simplified viewpoint with limited consideration to the fact that the synergistic effect of mechanical loads, environmental factors, and material heterogeneity. These traditional methods are not accurate in predicting long-term performance since they don’t fully integrate thermal, mechanical, and moisture-related interactions. In addition, most of the models do not include crack initiation and propagation under cyclic freezing and thawing in real environments. Constant temperature and moisture level tests lead to the unrepresentative behavior of asphalt and have limited application. Thus, asphalt should be subjected to more complicated temperature and moisture level variations where you need to consider the material nonlinearity as well as the damage mechanism. Advanced numerical modeling, particularly through the Finite Element Method (FEM), offers a more accurate and detailed analysis of stress distribution, strain evolution, and structural degradation (Lövqvist et al. 2021). A robust FEM-based simulation framework is developed to improve predictive capabilities and to provide valuable insights for asphalt mix design optimization that leads to asphalt pavement durability in cold climates.

2.4 The Role of Finite Element Method (FEM) in Asphalt Analysis

FEM stands as a research tool that helps scientists analyze complex dynamic material responses in interaction conditions. The model demonstrates an accurate representation of asphalt mixture freeze-thaw reactions through combined models of thermal effects with mechanical forces and moisture effects. Heterogeneous materials undergo analysis efficiently through FEM rather than FDM's ability to process irregular geometric shapes. As a successful technique for analyzing granular materials, DEM does not function properly with continuous and viscoelastic substances such as asphalt. FEM allows researchers to discover accurate stress distributions as well as strain evolution paths and cracking development during analyses which leads to enhanced predictions of pavement performance over time. Asphalt mix design enhancement depends on this tool that identifies local weaknesses and determines future structural breakdown patterns (Lövqvist et al. 2022). The analysis performed by FEM considers environmental elements together with mechanical forces to study asphalt freeze-thaw behaviors thus establishing a better understanding of pavement structures' freeze-thaw vulnerabilities when subjected to severe temperatures.

2.5 Contribution of This Research

The presented research created a finite element model for predicting how asphalt mixtures perform after repeated freeze-thaw cycling. The model integrates thermal effects with mechanical loading alongside moisture content for simulating actual pavement behavior in real-life scenarios. Response models of asphalt deterioration become more precise through the integration of stress-strain analysis with stiffness degradation and crack propagation into the model framework. Improvements in asphalt mix designs for cold climate durability coupled with cheaper maintenance will result from the obtained findings. The research also offers a framework for assessing asphalt performance using numerical simulations rather than enormous experimental testing. Sensitivity analysis provides confidence for the use of the model in data-driven decision-making for pavement design and rehabilitation using reliable engineered design procedures (Lu and Si, 2024). The work informs infrastructure planning through identifying key material properties that affect freeze-thaw resistance, to produce better sustainable road construction practices. The insights contribute to extending the pavement life and reducing the economic and environmental impact of pavement degradation.

3. Methodology

3.1 Research Approach

The effects of freeze-thaw cycles on asphalt mixtures are evaluated in this research which harnesses a combination of numerical simulations and data analysis. The effects of thermal, mechanical, and moisture-related interactions within the asphalt structure are simulated using a finite element model. A systematic approach is followed in the methodology starting from material property characterization and model setup and then freeze-thaw cycle simulation under controlled boundary conditions. Asphalt structural integrity after experiencing freeze-thaw cycles is simulated in mechanical testing, such as resilience modulus, flexural strength, and tensile strength testing. The validity of the data collected from the simulations is validated by comparing it to experimental findings. Refinement of input parameters and increasing the precision of the model are performed through sensitivity analysis (Mousavi Rad et al. 2022). The study is aimed at having an understanding of asphalt deterioration mechanisms to optimize pavement materials and maintenance strategies to achieve improved performance under cold climate environments.

3.2 Selection of FEM Software

The chosen tool for this study is COMSOL Multiphysics given its capability of modeling with a high level of multiphysics, its ease of use with the user-friendly GUI, and its ability to cope with complex material behavior. The physics built into the software are prebuilt modules that enable you to create a model faster. Due to the ability to couple the thermal, mechanical, and moisture-related phenomena arising in asphalt mixtures during freeze thaws, it is very suitable in developing models for asphalt mixtures undergoing freeze thaws. The COMSOL scripting language, as opposed to other finite element software like ABAQUS and LS-DYNA, offers greater adaptability from a manipulable point of view in which simulations can be customized solely for the need of the research (Qian et al. 2023). Adequate stress-strain techniques and crack propagation modeling based on robust meshing techniques are ensured by the software. The simulation software provided by COMSOL achieves these large-scale operations with superior precision efficiency. DALEX delivers the best framework to analyze asphalt degradation across different climate areas thereby producing researchers who develop longer-lasting and more efficient pavement systems.

3.3 Model Development

The constructed finite element models of asphalt pavements built by research analysts enable observation of reactions that occur during freeze-thaw cycles. Proper simulation of asphalt material behavior requires essential properties related to stiffness and thermal conductivity together with moisture diffusion coefficient and fracture toughness. Real-life environmental hazards involving temperature changes and mechanical wear enter through specified boundary conditions of the model. The model experiences multiple execution steps that relate to two main procedures and internal stress development results from pore moisture penetration followed by freeze-thaw methods. A refined mesh design enables the model to identify the correct points of initial cracking development and track their advancement (Ren et al. 2024). It is designed to simulate such a complex.lineWidth: lines.width.sets and allows a thorough investigation of asphalt degradation concerning temperature changes, moisture movement, and mechanical stresses. This detailed approach guarantees that the model replicates the material behavior under realistic freeze-thaw conditions, developing essential information about long-term behavior.

3.4 Freeze-Thaw Simulation Parameters

The freeze-thaw simulation considers various environmental and material factors similar to actual field conditions. Simulation of cyclic freezing and thawing is accomplished by defining temperature variation to which a particular temperature range represents seasonal variation. Thermal stresses are induced by these cycles and affect the material response. Water was absorbed into the asphalt, then ice formed in the asphalt’s pores during freezing, these phenomena are modeled to generate the moisture infiltration. It contributes to the formation and propagation of the crack. The crack growth analysis considered the progression of microcracks and its implications for the material structural integrity (Tabasi et al. 2023). During multiple freeze-thaw cycles, degradation of stiffness, tensile strength, and overall durability is tracked through stress-strain responses. Combining these factors in the simulation gives an integrated view of the asphalt behavior through freeze-thaw conditions for long-term material performance prediction, and failure mechanisms prediction.

3.5 Mechanical Testing Simulations

The performance of the asphalt mixture exposed to freeze-thaw cycles is evaluated by mechanical testing simulation. The parts of these virtual tests included the Resilience Modulus Test, Flexural Strength Test, and Tensile Strength Test, focusing on the individual properties of the strength of asphalt. This test involves repeat freeze-thaw cycles and measures the material’s stiffness and its stiffness at a reduced modulus (Wang et al. 2024). Both the Flexural Strength Test measures asphalt resistance to flexural cracking and the Tensile Strength Test reveals the point at which asphalt material initiates cracks under tensile stress. Scientific testing environments help researchers monitor freeze-thaw effects on asphalt mechanical properties to develop robust asphalt mixtures. The examination results enable better planning of pavements in cold climate areas.

3.6 Data Collection, Calibration, and Validation

During each run of simulation through the system, researchers obtain results containing information about stress distribution patterns alongside measurements of strain development and observations of crack formation throughout freeze-thaw processes. During the calibration stage, the model requires adjustments for its parameters until test results corresponding to replicated testing conditions are matched successfully. The quantitative validation tests use simulation results by comparing them against freeze-thaw qualification information that laboratories have recorded (Wu et al. 2023). A verified model delivers accurate asphalt behavior predictions for engineers to utilize it during road design tasks as well as routine maintenance procedures. The validated predictive model functions as a beneficial tool to determine asphalt lifetime under different environmental exposure conditions.

3.7 Documentation and Practical Implications

Engineers together with road construction and maintenance leaders can implement all research findings by accessing an extensive presentation format. Research results show fundamental aspects of asphalt freeze-thaw responses along with development recommendations for asphalt structures. The simulated outcomes assist engineers in optimizing maintenance programs while achieving economical solutions that maintain road networks (Xia et al. 2024). The model demonstrates effective prediction capacity for future road infrastructure projects which produces reliable applications during forthcoming projects while cutting down repair costs and improving resource allocation.

Technical engineering assignments involving FEM modelling, material degradation, and freeze–thaw analysis demand strong analytical structuring and precise academic writing. If you need support with literature synthesis, methodology presentation, or translating complex simulations into clear, high-scoring coursework, professional assignment help can ensure technical accuracy, clarity, and compliance with engineering assessment criteria.

References

Gao, M., Zhang, H., Gu, Y., Zhao, S., Guo, Z. and Li, Y., 2023. Effects of freeze-thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures. Reviews on Advanced Materials Science, 62(1), p.20230116.

Guo, Z., Wang, L., Feng, L. and Guo, Y., 2022. Research on fatigue performance of composite crumb rubber modified asphalt mixture under freeze thaw cycles. Construction and Building Materials, 323, p.126603.

Haghighatpour, P.J. and Aliha, M.R.M., 2022. Assessment of freezing and thawing cycle (FTC) effects on mixed mode I/III fracture toughness and work of fracture of HMA asphalt mixtures. Theoretical and Applied Fracture Mechanics, 118, p.103261.

Han, D., Liu, G., Xi, Y. and Zhao, Y., 2023. Research on long-term strength formation and performance evolution with curing in cold recycled asphalt mixture. Case Studies in Construction Materials, 18, p.e 01757.

Lövqvist, L., Balieu, R. and Kringos, N., 2021. A micromechanical model of freeze-thaw damage in asphalt mixtures. International Journal of Pavement Engineering, 22(8), pp.1017-1029.

Lövqvist, L., Balieu, R. and Kringos, N., 2022. Multiscale model for predicting freeze-thaw damage in asphalt mixtures. International Journal of Pavement Engineering, 23(14), pp.5048-5065.

Lu, F. and Si, W., 2024. Reliability risk modelling of asphalt pavement structure performance under the impact of freeze-thaw cycles. Case Studies in Construction Materials, 20, p.e03054.

Mousavi Rad, S., Kamboozia, N., Anupam, K. and Saed, S.A., 2022. Experimental evaluation of the fatigue performance and self-healing behavior of nanomodified porous asphalt mixtures containing RAP materials under the aging condition and freeze–Thaw cycle. Journal of Materials in Civil Engineering, 34(12), p.04022323.

Qian, N., Luo, W., Ye, Y., Liu, Y., Yin, D., Zheng, B. and Peng, H., 2023. Effects of the ductility and brittle point of modified asphalt on the freeze-break behavior of asphalt concrete: A 3D-mesoscopic damage FE model. Construction and Building Materials, 386, p.131555.

Ren, H., Qian, Z., Huang, W., Chen, T., Cao, H. and Liu, Y., 2024. Coupled effects of UV radiation and freeze–thaw cycles on the fracture behavior of asphalt concrete. Theoretical and Applied Fracture Mechanics, 133, p.104567.

Tabasi, E., Zarei, M., Alaei, H., Tarafdar, M., Alyousuf, F.Q.A. and Khordeh Binan, M.W., 2023. Evaluation of long-term fracture behavior of hot mix asphalt modified with Nano reduced graphene oxide (RGO) under freeze–thaw damage and aging conditions. Construction and Building Materials, 374, p.130875.

Wang, Y., Gu, H., Gu, C., Shao, C., Jiang, Z., Wang, Y. and Chen, X., 2024. Analysis of concrete damage evolution in cold regions under combined freeze-thaw cycle-crack effect. Construction and Building Materials, 456, p.139296.

Wu, C., Zhu, X. and Si, W., 2023. Sensitivity analysis of asphalt pavement performance under freeze-thaw cycles by applying a reliability method. Case Studies in Construction Materials, 19, p.e02656.

Xia, C., Xu, M., Li, Q., Liu, K. and Jiang, K., 2024. Study on the Freeze–Thaw Cycle Durability of Bamboo Fiber Asphalt Mixture. International Journal of Pavement Research and Technology, 17(3), pp.535-548.

Zhang, F., Li, X., Wang, L., Xue, Z. and Guo, Z., 2024. Effects of freeze-thaw cycles on fatigue performance of asphalt mixture and a fatigue-freeze-thaw damage evolution model. Construction and Building Materials, 449, p.138427.

Zhang, M., Xiong, Z., Gong, M., Hong, J., Qiao, H. and Zhang, Y., 2024. Multi-scale damage characterisation of semi-flexible pavements under freeze-thaw cycles. Construction and Building Materials, 445, p.137847.